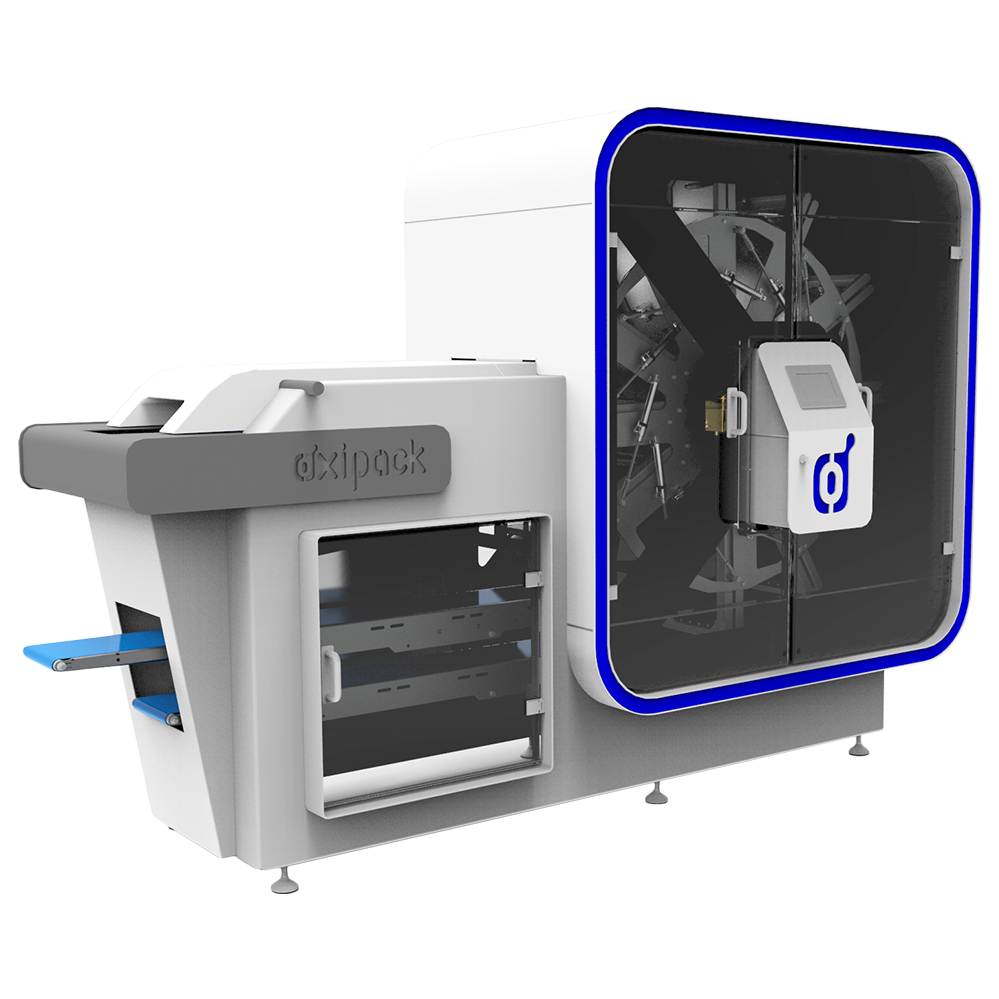

The Rotator R-20 up to R-120

The Oxipack Rotator is an automated, in-line leak detection solution for flexible MAP-packages, enabling you to maintain complete control over the process and the quality of your production line. The tester has a testing capability from 20 up to 120 packages per minute.

The Rotator is fully integrated into the production line, ensuring a seamless and streamlined integrity check. The universal chambers of the Rotator allow for simultaneous testing of different MAP packaging types, providing instant feedback on the package integrity of your products. Maintenance is made easy with

removable chambers.

The Oxipack Rotator is an automated, in-line leak detection solution for flexible MAP-packages, enabling you to maintain complete control over the process and the quality of your production line. The tester has a testing capability from 20 up to 120 packages per minute. The Rotator is fully integrated into the production line, ensuring a seamless and streamlined integrity check. The universal chambers of the Rotator allow for simultaneous testing of different MAP packaging types, providing instant feedback on the package integrity of your products. Maintenance is made easy with removable chambers.

Working principle: packages are presented to the Rotator’s conveyor belt, where they are positioned on a shooting belt that places them into the test chamber. The chamber consists of a rigid bottom plate and a flexible membrane top, which closes when the package is inserted. The machine then rotates to the next position, and the leak test begins by creating a vacuum. The next package is inserted into the chamber, and the cycle repeats. Once all packages are tested, the chamber opens, and the packages are sorted onto either the reject or OK belt. The rejected packages are directed to a separate bin for inspection, while the OK packages continue down the production conveyor belt.

Features:

• Non-destructive

• Accurate

• Direct results

• Fully integrated in production line

• Each package tested individually

• Complete control over integrity check

Dimensions and Weight: 3370 x 1100 x 2280 mm (L x W x H) 1825 KG

Power supply: 2P + PE 100 – 230VAC 50/60Hz

Materials: Stainless steel, Anodised aluminium, POM, Polycarbonate

Air supply: 6-8 bar

Compliance and IP rating: CE and IP40

Ambient temperature: 0 – 30 ˚C

Ambient relative humidity: Max 80% (non-condensing)

Size measuring chamber: 350 x 118 x 80 mm (L x W x H)

Maximum testing capacity: 20 PPM

Number of lanes: 1

Number measuring unit: 12

Leak detection method: ASTM F2338

Connections: USB/Ethernet export, 24VDC logic (free programmable)

Packaging type: MAP

Options: Line communication, Automated in and outfeed, Oxipack LED ++ package