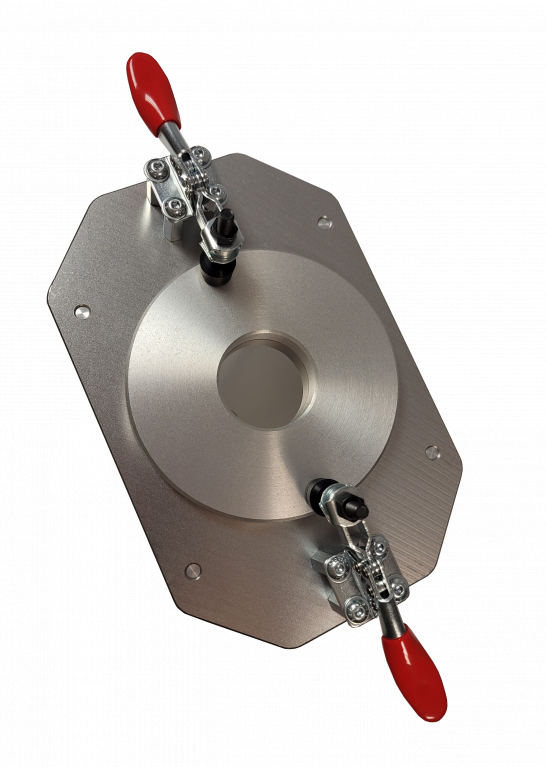

Puncture / Burst Test Jig

Puncture / Burst Test Jig for use with a Universal Testing Machine

Puncture resistance is a useful characteristic to determine the performance of a thin film particularly when packaging items that are likely to pierce the film, such as sharp, pointed, and hard items of food, electronics, medical devices etc.

Several testing methods describe the tooling/hardware, sample preparation, test parameters, and measured results, including ASTM, ISO, DIN and JIS methods.

Hardware – a Universal Testing Machine (e.g. SST-3XS) with load cell, fitted with a sample film clamp spanning an orifice of defined size and a puncture probe with sharp, ball or flat end. RDM supply various sizes to meet test standards.

Sample Preparation – as defined in the standards. Sample cutting is normally rough and does not require any special tools.

Test Parameters – speed of travel of the puncture probe into the sample film must be controlled to achieve correct comparison of different films. These methods use slow rate penetration e.g. 100 mm/min, conversely high speed impact resistance can be tested using a Falling Dart Impact Tester such as the model FD-1709.

Measured Results – typically the maximum force to penetrate in Newtons, kgs, lbf. Also the energy and deflection to break can be useful for comparison.

RDM provide several standard jigs that can fit to most makes of Universal Testing Machine, e.g. GP81 to ASTM F1306 (orifice 35mm, dome end 3.18mm) and GP80 to DIN EN14477 (Orifice 10mm, ball end 0.8mm). Other sizes available as required. Other standards include: ASTM D3787, ASTM D4833, ASTM D5748, JIS Z1707.

GP81 shown in image above.

RDM Test Equipment have set the standard in precision and reliability for over 30 years. Please Contact Us and we’ll work with you to understand your requirements and provide a solution.