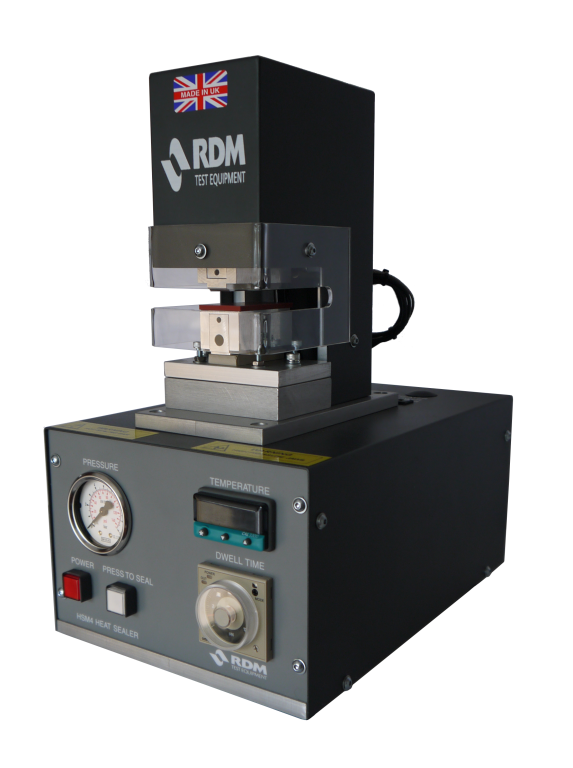

HSM-4 Laboratory Heat Sealer

For standard determination of heat sealability. Produces seals up to 50mm long x 5 to 25mm wide.

Precise control of heat sealing process variables (temperature, pressure, and dwell time), enables an optimal balance of material specification, packaging machine speed and seal integrity. Accuracy and repeatability in laboratory heat seal testing is vital, and the HSM-4 provides a standard range of controls for this purpose.

HSM-4 Mini Heat Sealer

The satisfactory development, manufacture, conversion and application of flexible packaging films necessitates the implementation of precise methods of quality control systems. The HSM-4 was developed to precisely control the parameters essential in determining the heat seal threshold. Especially suited for flexible packaging materials, laminates, foils and paper, the HSM-4 features accurate control of temperature, pressure and dwell time of a standard surface area sealing jaw. With the introduction of a standard test method ASTM F2029 and our heat sealer HSM-4, you can be confident that your heat seal threshold measurement is common to all producers, converters and end users of flexible packaging materials and their eventual applications.

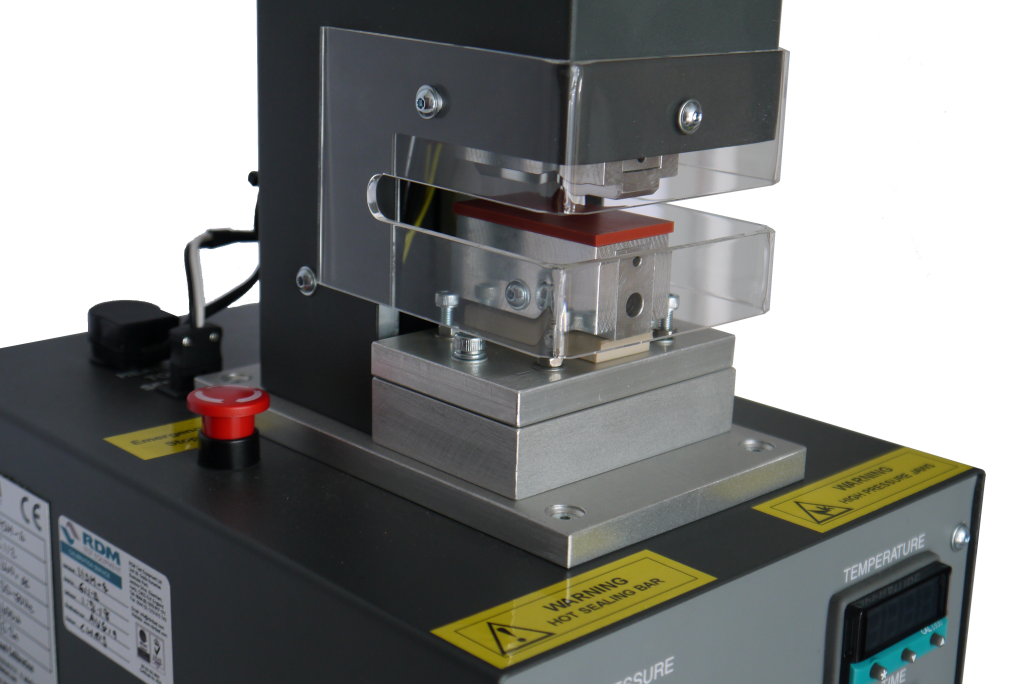

The HSM-4 also features a unique method of quick change over jaws, the machine employs a slide-on jaw arrangement. The machines comes with dovetailed blank heater blocks, in single or dual option, where standard flat ground surface slide-on jaw is supplied. When profiled crimp sealing surface is needed, mating dovetailed slide-on jaw are replaced very easily

Features:

- Pressure calibration of standard surface area jaw face

- Temperature digital controller, pressure and dwell time dial controllers

- Jaws constructed in aluminium and silicon with precision ground faces

- Range of jaw face surfaces including Matched Crimp and Teflon Coating

Benefits:

- Choose heat sealing bar configuration, either single (upper) or dual (upper & lower, meets ASTM F2029)

- User can easily change sealing bar for various surface areas or surface finishes

- Accurate and repeatable seals due to precision ground sealing faces and jaw guidance system

- Versatile applications for flexible materials, blister packs and pots

- Low Maintenance – 12 months between calibrations

Temperature Control

0 – 300ºC (0 – 572ºF) 0.1ºC resolution +/- 0.5% +/- 1 digit accuracy. Operating temperature accuracy +/- 2ºC. Resistance Type ‘J’ thermocouple sensing. Single independent or dual independent control.

Pressure: 0 – 100psi (0 – 6.8 bar, 0 – 689 Kpa) via dial pressure gauge. Pressure control through precision regulator. Repeatability +/-5.0 PSI Operation accuracy +/- 10% Supply via factory compressed air line or nitrogen or compressed air bottles min 6 bar (90 psi) max. 7 bar(100 psi). Pressure medium must be clean and dry.

Dwell Time: 0.1 – 99.9 sec. 0.1 sec resolution real time base via quartz crystal +/- 0.5% of range. Operating accuracy +/- 10% (taking into account friction in piston movement).

Footswitch: Connection port for footswitch operation. Optional footswitch.

Sealing Jaw: Single jaw option: Top heated with silicone rubber (60 shore hardness) 5mm – 25mm wide x 50mm long. Jaws made from aluminium with machine ground flat face. Dual jaw option: Top and Lower heated 5mm – 25mm wide x 50mm long. Jaws made from aluminium with machine ground flat face.

Environment: 5-50C ambient operating temperature, RH 75% max (non-condensing)

Power: 240V AC 50/60 Hz (110V AC voltage available on request)

Options

Footswitch.

PVC Dust cover.

Up-grade to digital dwell timer.

Crimp profiled slide-on jaws 120degree x 1.8 mm pitch.

Cold Seal Option (temperature circuit re-moved) supplied with flat or crimp profiled jaws.

Teflon coated tape or permanent Teflon coating Digital thermometer and s/s band probe to check the actual temperatures of sealing Jaw.