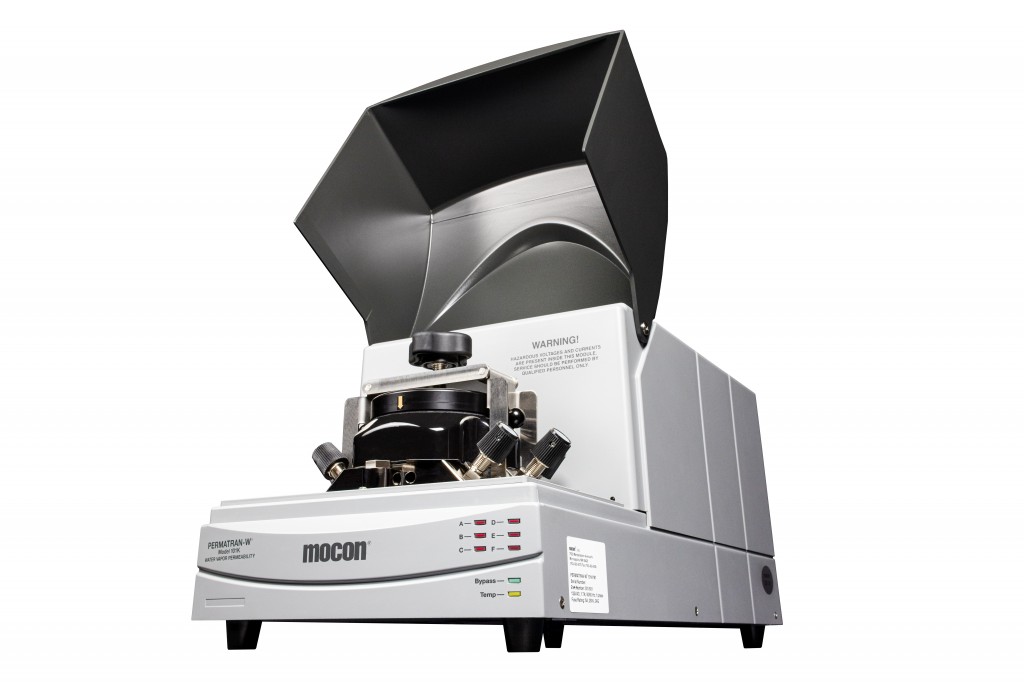

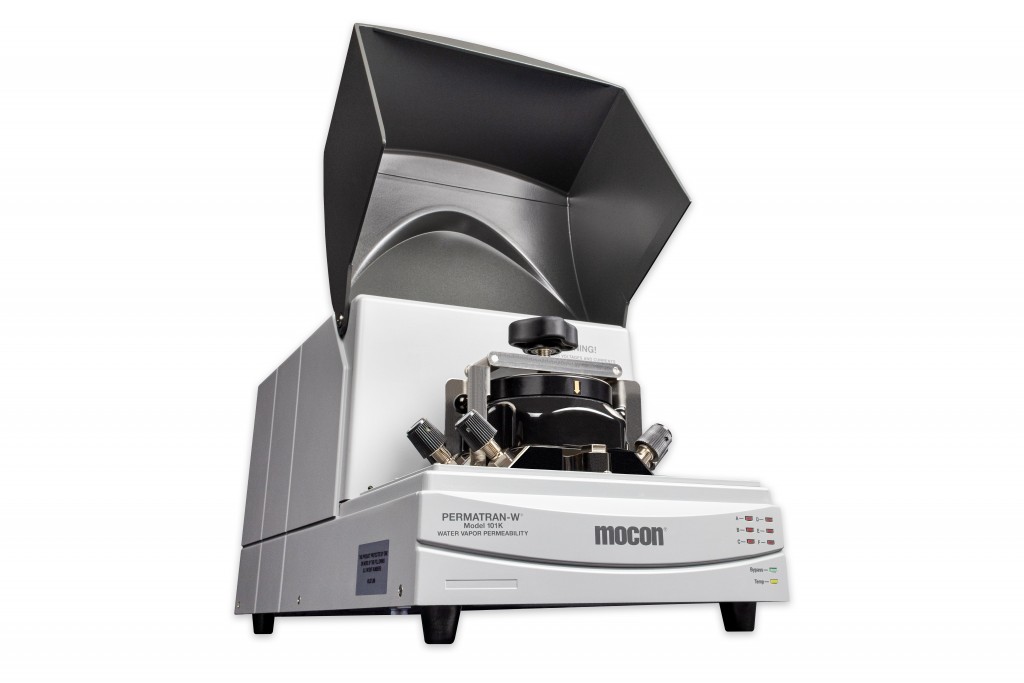

PERMATRAN-W® Model 101K

WVTR transmission rate testing of non-wovens, fabrics, textiles, breathable membranes, plastic films and paper.

The PERMATRAN-W® 101K is a 6-cell instrument allowing you to test up to 6 samples at the same conditions simultaneously. The unique design allows accurate true permeation measurement through the samples that reflect real-life situations.

The PERMATRAN-W® 101K is a 6-cell instrument allowing you to test up to 6 samples at the same conditions simultaneously. The unique design allows accurate true permeation measurement through the samples that reflect real-life situations.

High Accuracy

- Unique RH control allows repeatable testing to ASTM D6701

- Measures transmission rate of water vapor or moisture vapor through the porous and breathable polymer membranes, polymer coated thin paper, and thin polymer nonwoven.

- Measure WVTR of higher-level transmitters up to 101,000 g/(m2*day)

- Precise temperature measurement and control

High Throughput

- Test breathable membranes, coated paper and more

- Unique test method is faster and more accurate than Gravimetric Methods

- Parallel testing of 6 samples at a time

The PERMATRAN-W 101K is designed to test the Water Vapor Transmission Rate (WVTR or MVTR) on breathable barriers efficiently and accurately. Testing highly permeable materials with the traditional Gravimetric method is subject to driving force issues caused by an air gap that leads to inconsistent and erroneous test results.

The 101K WVTR analyzer utilizes a modified inverted water cup concept that eliminates the air gap problem and maintains constant 100% RH throughout the test period providing accurate and repeatable results. Designed for high transmitter barriers this analyzer provides test results from 500 to 101,000 g/(m2*day) while conforming to the ASMT D6701 standard that is specific written for this instrumental method.

The instrument has an easy to use operator interface and can be connected to other MOCON instruments providing centralized control and monitoring of multiple instruments. It has fully adjustable temperature control with flow and barometric pressure correction capabilities.

For more than 25 years, MOCON’s PERMATRAN series of instruments have been the most trusted and longest lasting on the market. The 101K offers accurate water vapor permeation measurement for those breathable barriers not easily tested by other methods.

High Throughput

- Integrated 6-cell test head for parallel testing of 6 samples at the same time

- Compact test chamber area is easy to load

- Consistent test conditions across all 6 cells

- Single clamp provides repeatable results

Simple user interface

- Overview dashboard screen provides the status of all cells at a glance

- Automatically generated test reports contain complete test data and conditions for all 6 cells

- One control system can be connected to other MOCON instruments providing centralized monitoring and control for multiple instruments

Innovative RH control

- Maintains 100% RH throughout the test unlike gravimetric testers

- Does not require partial pressure for analysis

- True measurement of WVTR through porosity, permeation and diffusion

Warranty

- Full 100% parts and workmanship warranty for 12 months

Capabilities – All Models

| PERMATRAN-W 101K WVTR Analyzer | Units |

| Temperature Control Range | 20 °C to 50 °C ± 0.5 °C |

| Humidity Control, Film Cell, Test Gas | 100% |

| Test Range, Film, Unmasked (10 cm2) | 500 to 100,000 g/(m2 • day) |

| 32.5 to 6500g/(100in2 • day) | |

| Resolution, Film | 1.0 g/(m2 • day) |

| Repeatability, Film | 1% |

Physical Specifications

- 15.5” H x 12” W x 23” D (39.4 cm x 30.4 cm x 58.0 cm)

- 95 Lbs. (43.1 kg)

Electrical Requirements

- Voltage: 100 – 240 VAC 50/60 Hz

- Maximum Power Draw: 700 VA

Laboratory Requirements

| Temperature | Operation | 22 °C ± 2 °C |

| Storage | 10 °C to 30 °C | |

| Humidity | Operation | 20% to 80% RH (non-condensing) |

| Storage | 5% to 85% RH (non-condensing) |

Gas Supply Requirements

| Carrier Gas | Gas Composition | Nitrogen (99.99% N2 or better) |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) |

Connectivity

- Dual RS-485 ports (One for input from other instrument and one for output to a computer)

Cartridges & Options

- Special Sample cutting templates

Consumables

- Certified Film 1

Software

- Data collection software – PermNet

Service & Support Options

- Basic Preventative Maintenance Plan

- Plus Preventative Maintenance Plan

Specialty Materials

- Bandages

- Nonwoven materials commonly used for:

- Surgical masks (may contain Melt blown polypropylene)

- Medical PPE

- Baby Diapers

- Adult Diapers

- Feminine protection

- Porous and breathable polymer membranes commonly used for:

- Construction wrap

- Battery separation

- Filters

- Thin paper with polymer coatings

Test Standard Compliance

ASTM D6701

Test Methodology

Following ASTM D6701

Standard Test Method for Determining Water Vapor Transmission Rates Through Nonwoven and Plastic Barriers

Summary of Test Method

A dry chamber, guard film, and a wet chamber make up a diffusion cell in which the test film is sealed. A first test is made of the water vapor transmission rate of the guard film and air gap between an evaporator assembly that generates 100 % relative humidity. A sensor produces an electrical signal, the amplitude of which is proportional to water vapor concentration. The electrical signal is routed to a computer for processing. The computer calculates the transmission rate of the air gap and guard film and stores the value for further use. The barrier is then sealed in the test cell and the apparatus started in the test mode. As before, the electrical signal representing the water vapor is sent to the computer which then calculates the transmission rate of the combination of the air gap, the guard film, and the test barrier. The computer then uses this information to calculate the water vapor transmission rate of the material being tested. The computer determines when the measured results indicate that the specimens have reached equilibrium values and the testing is considered finished.