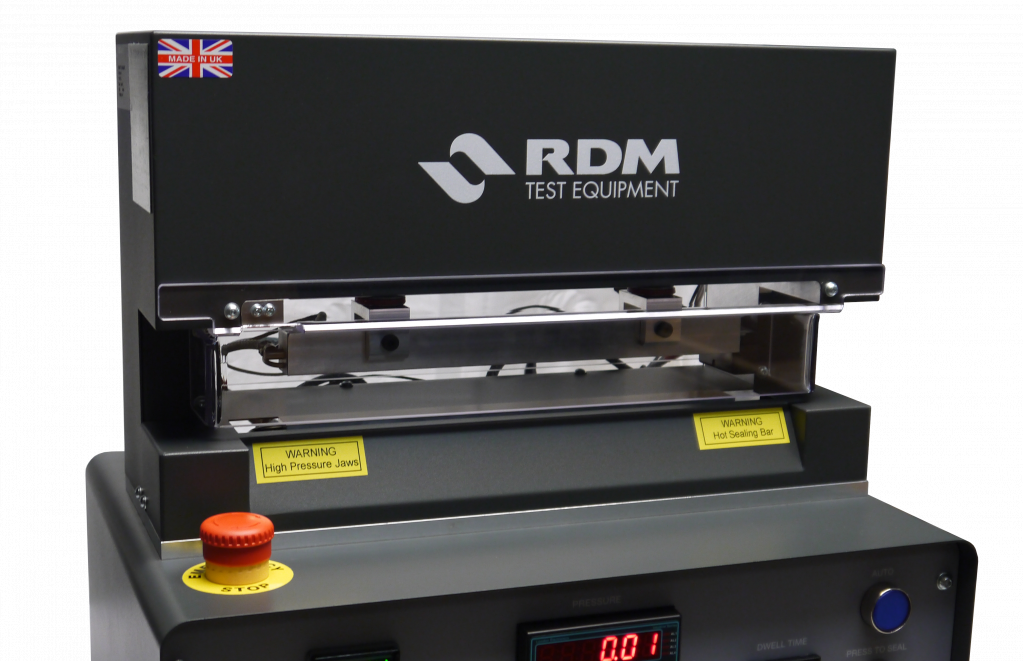

Precise control of heat sealing process variables (temperature, pressure, and time), enables an optimal balance of material specification, packaging machine speed and seal integrity. Accuracy and repeatability in laboratory heat seal testing is vital, and the HSE-3 provides precision digital controls for this purpose.

Features:

- Precise pressure calibration of standard surface area jaw face

- Temperature, pressure and dwell time digital controllers

- Jaws constructed in aluminium and silicon with precision ground faces

- Range of jaw face surfaces including Matched Crimp and Teflon Coating

- Auto cycle feature for greater user convenience with multiple samples

Benefits:

- Choose heat sealing bar configuration, either single (upper) or dual (upper & lower, meets ASTM F2029)

- User can easily change sealing bar for various surface areas or surface finishes

- Accurate and repeatable seals due to precision ground sealing faces and jaw guidance system

- Versatile applications for flexible materials, blister packs and pots

- Low Maintenance – 12 months between calibrations

HSE-3 Laboratory Heat Sealer meets the following standard: ASTM F2029

RDM Laboratory Heat Sealers have set the standard in precision and reliability for over 30 years. Please Contact Us and we’ll work with you to understand your requirements and provide a solution.

Specification

Seal Width: 300 mm max. (Option to extend to 350mm)

Temperature Control: Range: Ambient to 300°C, Accuracy: +/- 0.5%, Operating Accuracy: +/-2°C. Single (Upper) sealing jaw temperature control, or Dual (Upper & Lower) sealing jaw temperature control.

Pressure: Range: 0 to 100psi (6.8bar, 689Kpa), via precision regulator and digital display. Accuracy +/-5%, Repeatability +/- 0.02psi .

Supply via clean and dry compressed airline or bottled air/nitrogen at 90 to 100psi

Dwell Time: Range: 0.1 to 99.9 sec., Resolution 0.01 sec

Auto Cycle & Delay Time: Delay Time Range: 0.1 to 99.9 sec For automatic cycling of sealing bars used in manual production environments. Assists with correct alignment of sample. Electronic processor controlled.

Jaw Guidance System: Dovetail slide on jaws with quick release mechanism.

Sealing Jaws: Standard flat jaws 25mm x 300mm, constructed in aluminium with precision ground face. Lower sealing jaw with precision ground silicone rubber face. (See options below)

Environment: 5-50°C ambient operating temperature, RH 75% max (non-condensing)

Power: 240V AC 50/60 Hz (110V AC voltage available on request)

Dimensions: W 50 x D 41 x H 49cm, 28kg

Options

• Single (Upper) sealing jaw temperature control or Dual (Upper & Lower) sealing

jaw temperature control

• Sealing jaw dimension/profile as required (inc. Matched crimp 120° x 1.8mm pitch)

• Stainless Steel sealing jaws

• Teflon Coated Tape or Teflon Coated Jaws

• Blister Pack Simulator sealing jaw

• Additional Blister tray

• Footswitch

• PVC Dust Cover

• Alarm package for temperature High/Low, selectable

• Cold seal system

• Digital thermometer with s/s band probe to check jaw

temperature (see image)