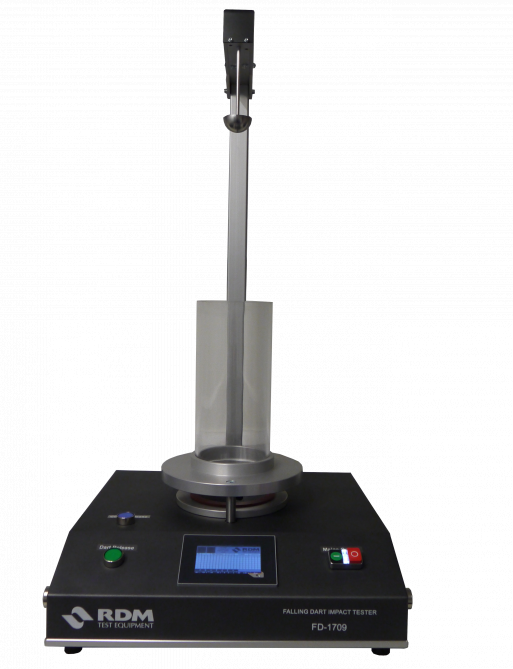

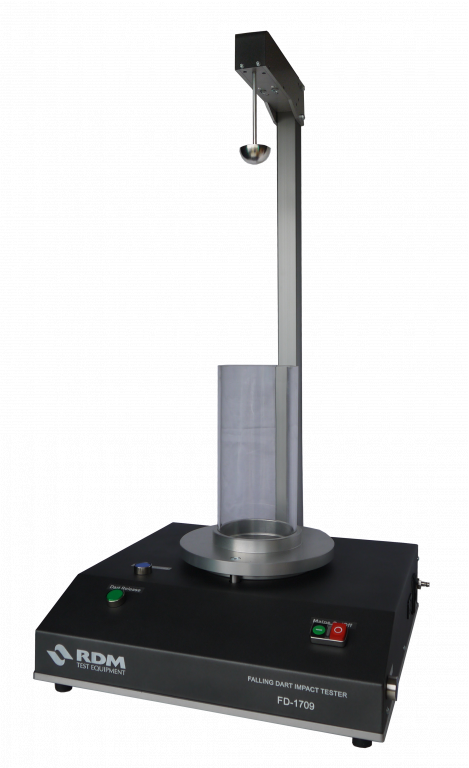

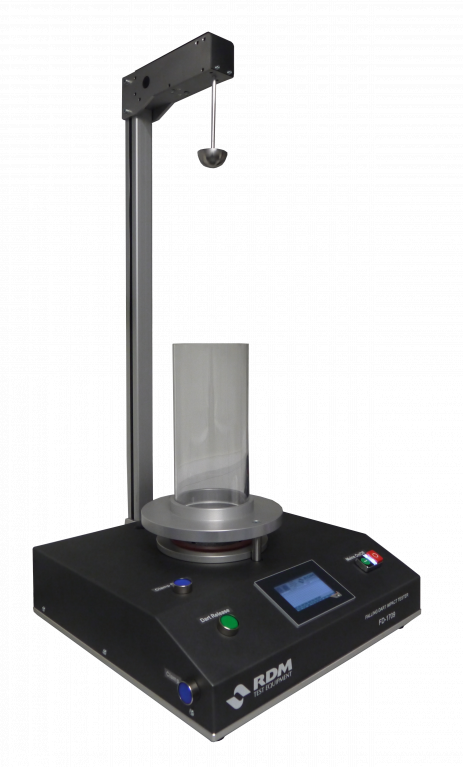

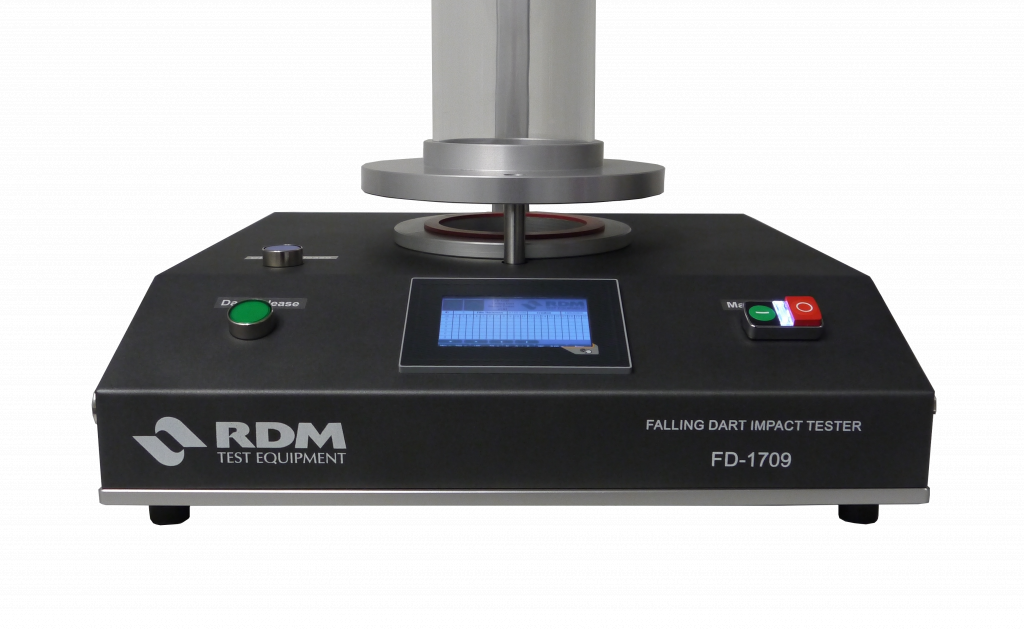

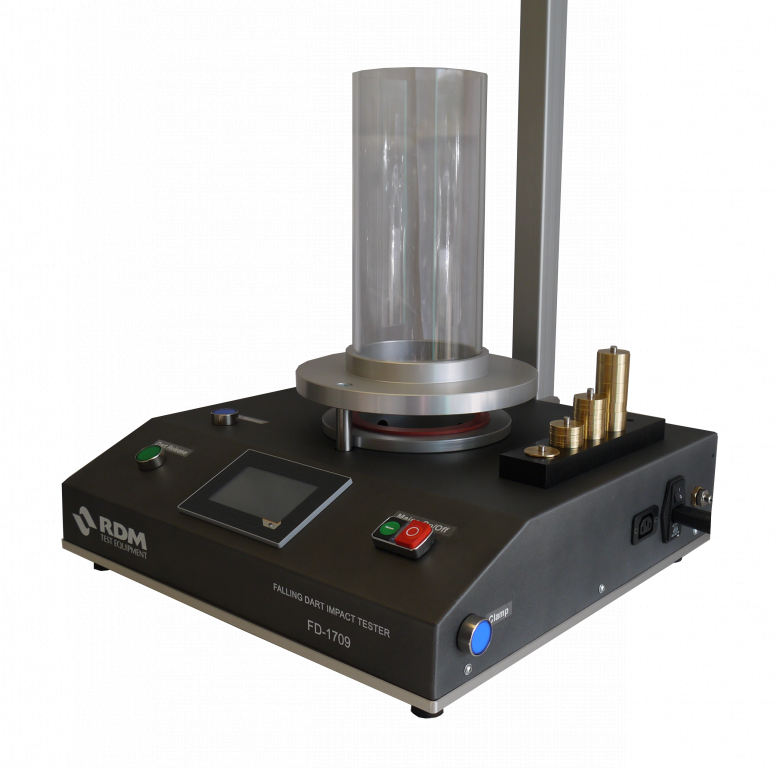

The FD-1709 is a cost effective solution for testing impact resistance of sheet materials. Bench mounted or floor standing, with drop heights and darts for ASTM D1709 Methods A & B. Operation is by push button, and an optional touchscreen provides a standard operating procedure and test traceability. Impact resistance is expressed as the mass of a free falling ‘missile’ that would cause failure of 50% of samples tested. A simple pass/fail procedure, combined with varying weights enables calculation of the resulting mass. A variety of factors can affect impact resistance including material thickness, uniformity of thickness, sample clamping, dart weight and drop height.

Procedure

The FD-1709 with optional built in touchscreen guides the user through the series of tests, and calculates the result on completion. The procedure starts with an initial weight, then on each test drop the outcome (break / no break) is recorded and the weight for the following test indicated, after the specified number of tests, the final result is displayed and saved. Without the touchscreen, tests are performed and recorded manually. The dart missile has a release clamp making it very quick and easy to add or remove weights, and is capable of holding up to 2000 grams (most models have a limit of below 1,000 grams), meaning the FD-1709 is suitable for a wide range of light and heavy test materials. The dart release mechanism ensures user safety and a consistent drop height. The pneumatic sample clamp is operated by twin push buttons to ensure user safety. This provides repeatable clamping pressure and prevents slippage of sample materials.

FD-1709 Falling Dart Impact Tester meets the following standards, click on the links to purchase the standards ASTM D1709 and ISO 7765.

RDM Test Equipment have set the standard in precision and reliability for over 30 years. Please Contact Us and we’ll work with you to understand your requirements and provide a solution.

Features & Benefits

• Push button operation or optional digital touch screen panel which guides the user and calculates test results.

• Safe 2 handed operation of pneumatic sample clamp.

• Displays trend of results, next weight and final results.

• Manual sample counter, or touchscreen display of results.

• Conforms to ASTM D1709 and IS7765 for method A and method A & B.

Physical Specifications

Model FD-1709A: W x D x H: 510mm x 480mm x 1,020mm

Model FD-1709B: W x D x H: 510mm x 480mm x 1,870mm

Floor mounted cabinet: W x D x H: 510mm x 480mm x 450mm

Ordering Information

Model FD-1709A: supplied complete with 1.5” dome ended dart, fixed 0.66m drop height and weight set (2 x 5g, 8 x 15g, 8 x 30g, 8 x 60g).

Model FD-1709B: supplied complete with 1.5” and 2” dome ended darts, drop heights of 0.66m and 1.524m, and weight set (4 x 5g, 8 x 15g, 8 x 30g, 8 x 45g, 8 x 60g, 8 x 90g)

Item FD-1709/Touch: built-in touchscreen for test set-up and results.

Item FD-1709/Cab: Floor mounted cabinet.

Item FD-1709/KitB: Method B testing kit for retrofitting to FD-1709A to extend capability to Method B testing. Includes extension post for 0.66m and 1.524m, 2″ dart and additional weights (2 x 5g, 8 x 45g, 8 x 90g).

Applications

Plastic film, packaging films, paper, paperboard, corrugated board, foils, and other sheet like materials.