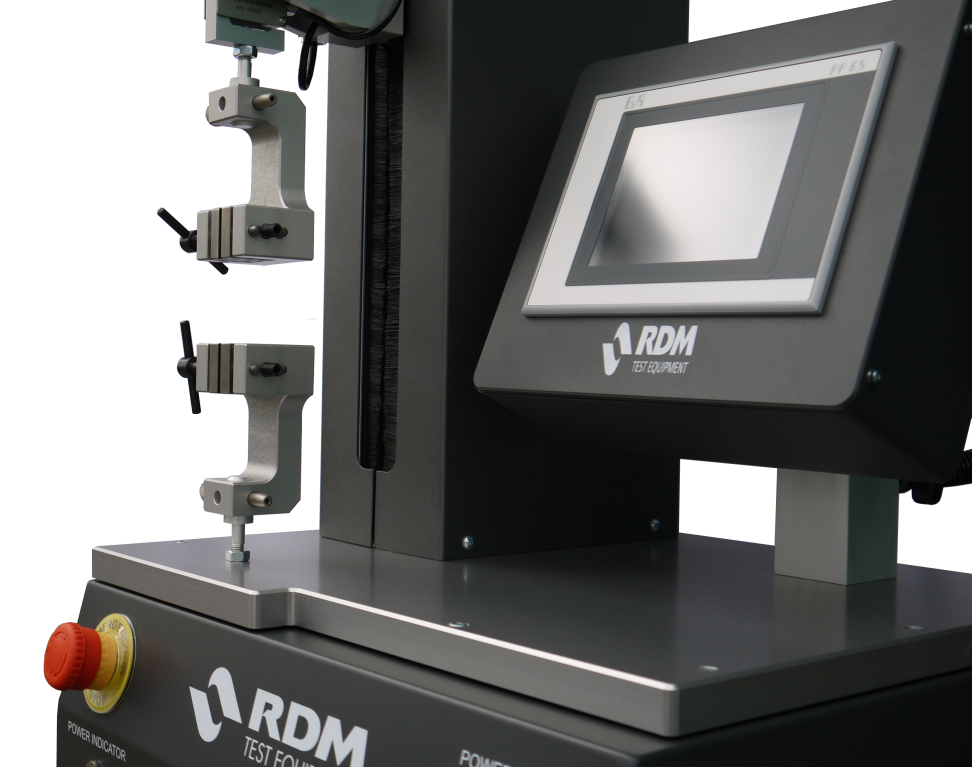

SST-3XS Seal Strength / Tensile / Compression Tester

Touchscreen Precision Seal Strength / Tensile / Compression Tester for determining the strength of packaging materials including plastics, paper and board.

Producing consistent and repeatable packaging for your product not only ensures minimal handling damage, but is vital in delivering a consistent brand to your customers. Precise measurement of the mechanical properties of materials and final packages is one way to ensure consistency and reduce material costs.

Accuracy and versatility in testing is vital, and the SST-3XS provides the technology and range of options to deliver for your specific needs. An intelligent controller and touch screen user interface stores multiple settings for later recall, and controls settings to ensure calibrated accuracy to international testing standards.

Benefits:

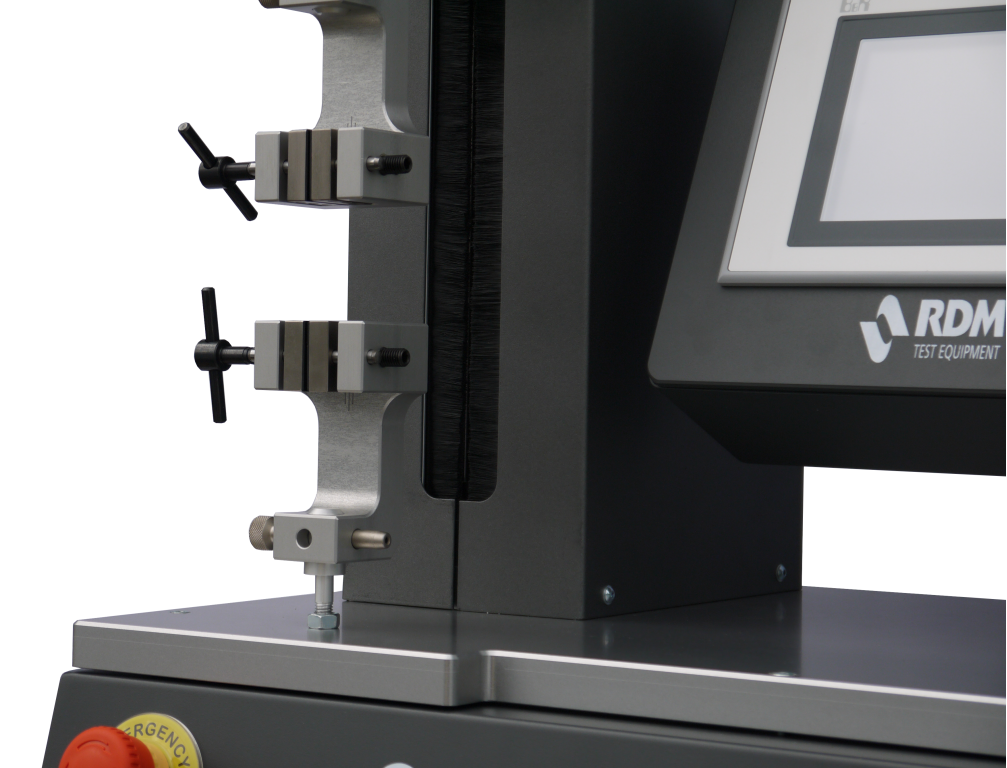

- Versatility to meet many international testing standards with packaging testing grips and attachments

- Integral controller and data analysis for stand alone use in laboratory and production environments, optional pc data acquisition

- Convenient built in graphical display of test data and trends over multiple samples

- Simple test set up and memory of settings for later recall makes switching between methods fast

- Low Maintenance – 12 months between calibrations

Features:

- 5.7″ touch screen controller for precise control and measurement of force, distance and speed

- Memory recipe function for quick and accurate recall of settings

- Standard 100N load cell, optional to 500N, interchangeable

- Standard 300mm crosshead travel, optional 550mm travel

Specifications

- Models: SST-3XS Mini (300mm travel) SST-3XS Maxi (500mm travel)

- Drive Mechanism: DC synchronous motor and gearbox with ball screw and crosshead

- Speed Control: 1mm/min to 1000mm/min +/- 0.5%

- Speed Feedback: Via in line encoder

- Touch Panel Screen: LCD, 256 Colour, QVGA, 320 x 240 pixels, 14.48cm diagonal viewing Touch screen, analogue resistive (gonze) with serial controller Processor Geode SC2200. 266 MHz MMX compatible. 2 mbyte, on board flash memory for firmware 64 MB Dram main memory

- Load Range: Selectable load cell;

- Standard Grips: Light duty side entry vice grips

- Travel: 300 mm or 550mm effective travel

- Output: RS 232

- Power: 80 – 240 VAC single phase 50/60 Hz 500W Max

- Environment: 5-50°C ambient operating temperature, RH 75% max (non-condensing)

SST-3XS Seal Strength Tester meets the following standard, click on the link to purchase the standard ASTM F88.

RDM Test Equipment have set the standard in precision and reliability for over 30 years. Please Contact Us and we’ll work with you to understand your requirements and provide a solution.

Removable Cartridges

- Easy sample prep on the benchtop

- One button release and loading

- Pneumatic clamping provides more repeatable results

- Interchangeable cartridge options extend the range and flexibility of the analyzer without tools while maintaining arcuate results

- Cartridge options include: Reduced area to extend testing range without masks, improved accuracy testing of coated paper-based barriers, adaptors for remote testing of packages or extreme conditions, and custom designs for unique testing requirements.

TruSeal®

- Gas flush of sample mounting seal protects chamber integrity

- Lowers background level reducing need to run individual zero

- Shortened testing time increases throughput

- More repeatable results

Control Features

- Fully automated flow, temp, & RH control throughout tests

- Automatic test method development and recommendations

- Programmable multi-test sequencing

- Final test report printing and export

- Built-in sensor protection

Touchscreen Interface

- Intuitive automated operation requires less training

- Built in multi-level user management and data security

- Event log & trouble shooting guide

- Save on valuable lab space by eliminating need for PC

Accurate Sensors

- 2/12 R model has wide range sensor providing reliable, repeatable results

- 2/12 T model has a unique high range Coulox sensor for high transmitter barriers

Warranty

- Full 100% parts and workmanship warranty for 12 months

Capabilities – Model-Specific

| Units | R Model | T Model | |

| Test Ranges (50 cm^2 @100%O2) | cc/(m2 × day) | 0.05 to 28,800 | 200 to 65,000 |

| cc/(100 in2 × day) | 0.003 to 1858 | 12.9 to 4200 | |

| Test Ranges (5.6 cm^2) @100%O2 | cc/(m2 × day) | 0.44 to 255,300 | 1770 to 576,200 |

| cc/(100 in2 × day) | 0.027 to 16,470 | 114 to 37,200 | |

| Test Range – Package | cc/(pkg × day) | 0.00025 to 144 | 1.0 to 323 |

| Resolution | cc/(m2 × day) | 0.05 | 2.0 |

| Repeatability | cc/(m2 × day) | 0.05 or 1.5%* | 25 or 1%* |

| Test Temperature Range | °C | 10° to 40°C ± 0.2°C | 10° to 35°C ± 0.2°C |

| Controlled RH Testing Range | % RH | 0 to 90% ± 3% | 0% |

*whichever is greater

Capabilities – All Models

| OX-TRAN 2/12 Series | Units |

| Film Size | 4” x 4” Std, 2”x2” optional |

| Film Thickness | Up to 120 Mil |

| Film Test Area | 50 cm2 cartridge std, |

| 5.6 cm2 cartridge optional |

Other Specifications (all models):

Physical Specifications

- 5.5” H x 12” W x 23” D (39.4 cm x 30.4 cm x 58.0 cm)

- 95 Lbs. (43.1 kg)

Electrical Requirements

- Voltage: 100 – 240 VAC 50/60 Hz

- Maximum Power Draw: 700 VA

Laboratory Requirements

| Temperature | Operation | 22 °C ± 2 °C |

| Storage | 10 °C to 30 °C | |

| Humidity | Operation | 20% to 80% RH (non-condensing) |

| Storage | 5% to 85% RH (non-condensing) |

Gas Supply Requirements

| Carrier Gas | Gas Composition | 100% Nitrogen |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) | |

| Test Gas | Gas Composition | 100% Oxygen (purity 99.9%) |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) |

Connectivity

- Remote Access and Control (requires optional Perm-Net Light software)

- Standard Ethernet port (100T)

- Dual USB 2.0 ports (for connection of keyboard, mouse or memory devices)

Compliance Standards

This product is UL and CSA listed using the ETL mark from Intertek Group plc. and is certified to conform to CE.

Conforms to the following internationally recognized safety standards.

- IEC 61010-1:2010 Third Edition

- UL 61010-1:2012 Third Edition

- CAN/CSA-C22.2 No. 61010-1:2012 Third Edition

Conforms to the following internationally recognized EMC standards.

- EN 61326-1:2013

- EN 61000-3-2:2006, A1:2009, A2:2009

- EN 61000-3-3:2013

Conforms to EU Directive 2011/65/EU RoHS Compliance.

Packaging Films

- Monolayer

- Multi-layer

- Coated Films

- Coated Paper/paperboard

Specialty Films

- Gel/lotions

Packages

- Common food packages

- Medical packages

- Bottles/Closures

Test Standard Compliance

ASTM F2622

ISO CD 15105-2

JIS K-7126-B

DIN 53380-3

Test Methodology

Following ASTM F2622

Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and

Sheeting Using Various Sensors

The oxygen gas transmission rate is determined after the sample has equilibrated in a controlled test environment. Control of carrier gas flow rate (for concentration detectors), relative humidity, temperature, and oxygen concentration in both the carrier gas and permeant (test) gas chambers is critical.

The specimen is mounted as a sealed semi-barrier between two chambers at ambient atmospheric pressure. A stream of nitrogen slowly purges one chamber and the other chamber contains oxygen. As oxygen gas permeates through the film into the nitrogen carrier gas, it is transported to the detector where it produces a signal representing the oxygen transmission rate.