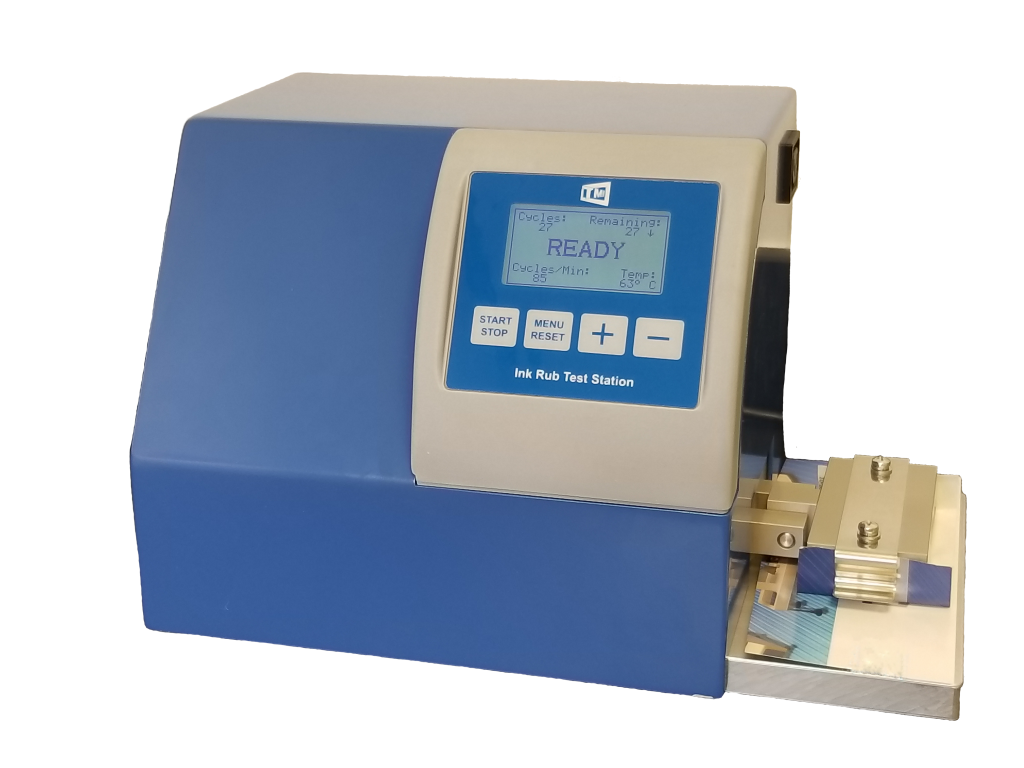

TMI 10-20 Digital Ink Rub Tester

The Digital Ink Rub Tester is designed to measure scuffing or rubbing resistance.

The Digital Ink Rub Tester is designed to measure scuffing or rubbing resistance. Several tests can be performed including dry rub-the amount of transfer ink from one dry surface to another, wet rub-the amount of transfer of ink from wetted surface to another, wet bleed or transfer-ink transfer to a water-saturated blotter, wet smear-similar to wet bleed with the addition or rub cycles, functional rub/wet rub-smear or transfer tests using a liquid other than water and hot abrasion. An optional heated weight provides a uniform test for evaluating “hot abrasion” resistance of printed cartons, labels etc.

Superceeds TMI Model 10-18 Digital Ink Rub Tester.

Applications

Coating Testing, Ink and Printability Testing, Package Testing, Surface Property Testing

Industries

Adhesives and Labels, Corrugated and Board, Flexible Packaging and Films, Inks and Coatings, Packaging, Paper and Pulp

Properties

Abrasion, Ink Rub

Standards

ASTM D 5264, ASTM F 1571, ASTM F 2497, FINAT FTM 27, TAPPI T-830

Specifications

- Includes (1) 1.8 kg(4 lb) weight, (1) 0.9 kg(2 lb) weight, spare rubber pads, and scoring fixture

- Heated weights 2 lb and 4 lb available

- Replacement Pads available

Features

- Five speeds – The standard speed (42 cycles per minute) and four additional speeds (21, 85, 100 and 106 cycles per minute) allow you to decrease the testing time for samples requiring a higher number of rubs

- Additional variable speed ranging from 20-115 cycles per minute

- Infinitely variable cycle count from 1-999

- Continuous cycle mode

- Large character LCD Display

- Displays count up, count down, test status and configurations

- Preset counts remain in memory

- Automatic shut-off

- Selectable “test complete” alarm

- One-year warranty

Instrument Size

| Depth: | 216 mm (8.5 in.) | ||

| Height: | 229 mm (9 in.) | ||

| Width: | 356 mm (14 in.) | ||

| Weight | 9.5 kg (21 lb) + weights |

Connections

Electrical: Specify voltage requirements when ordering

Removable Cartridges

- Easy sample prep on the benchtop

- One button release and loading

- Pneumatic clamping provides more repeatable results

- Interchangeable cartridge options extend the range and flexibility of the analyzer without tools while maintaining arcuate results

- Cartridge options include: Reduced area to extend testing range without masks, improved accuracy testing of coated paper-based barriers, adaptors for remote testing of packages or extreme conditions, and custom designs for unique testing requirements.

TruSeal®

- Gas flush of sample mounting seal protects chamber integrity

- Lowers background level reducing need to run individual zero

- Shortened testing time increases throughput

- More repeatable results

Control Features

- Fully automated flow, temp, & RH control throughout tests

- Automatic test method development and recommendations

- Programmable multi-test sequencing

- Final test report printing and export

- Built-in sensor protection

Touchscreen Interface

- Intuitive automated operation requires less training

- Built in multi-level user management and data security

- Event log & trouble shooting guide

- Save on valuable lab space by eliminating need for PC

Accurate Sensors

- 2/12 R model has wide range sensor providing reliable, repeatable results

- 2/12 T model has a unique high range Coulox sensor for high transmitter barriers

Warranty

- Full 100% parts and workmanship warranty for 12 months

Capabilities – Model-Specific

| Units | R Model | T Model | |

| Test Ranges (50 cm^2 @100%O2) | cc/(m2 × day) | 0.05 to 28,800 | 200 to 65,000 |

| cc/(100 in2 × day) | 0.003 to 1858 | 12.9 to 4200 | |

| Test Ranges (5.6 cm^2) @100%O2 | cc/(m2 × day) | 0.44 to 255,300 | 1770 to 576,200 |

| cc/(100 in2 × day) | 0.027 to 16,470 | 114 to 37,200 | |

| Test Range – Package | cc/(pkg × day) | 0.00025 to 144 | 1.0 to 323 |

| Resolution | cc/(m2 × day) | 0.05 | 2.0 |

| Repeatability | cc/(m2 × day) | 0.05 or 1.5%* | 25 or 1%* |

| Test Temperature Range | °C | 10° to 40°C ± 0.2°C | 10° to 35°C ± 0.2°C |

| Controlled RH Testing Range | % RH | 0 to 90% ± 3% | 0% |

*whichever is greater

Capabilities – All Models

| OX-TRAN 2/12 Series | Units |

| Film Size | 4” x 4” Std, 2”x2” optional |

| Film Thickness | Up to 120 Mil |

| Film Test Area | 50 cm2 cartridge std, |

| 5.6 cm2 cartridge optional |

Other Specifications (all models):

Physical Specifications

- 5.5” H x 12” W x 23” D (39.4 cm x 30.4 cm x 58.0 cm)

- 95 Lbs. (43.1 kg)

Electrical Requirements

- Voltage: 100 – 240 VAC 50/60 Hz

- Maximum Power Draw: 700 VA

Laboratory Requirements

| Temperature | Operation | 22 °C ± 2 °C |

| Storage | 10 °C to 30 °C | |

| Humidity | Operation | 20% to 80% RH (non-condensing) |

| Storage | 5% to 85% RH (non-condensing) |

Gas Supply Requirements

| Carrier Gas | Gas Composition | 100% Nitrogen |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) | |

| Test Gas | Gas Composition | 100% Oxygen (purity 99.9%) |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) |

Connectivity

- Remote Access and Control (requires optional Perm-Net Light software)

- Standard Ethernet port (100T)

- Dual USB 2.0 ports (for connection of keyboard, mouse or memory devices)

Compliance Standards

This product is UL and CSA listed using the ETL mark from Intertek Group plc. and is certified to conform to CE.

Conforms to the following internationally recognized safety standards.

- IEC 61010-1:2010 Third Edition

- UL 61010-1:2012 Third Edition

- CAN/CSA-C22.2 No. 61010-1:2012 Third Edition

Conforms to the following internationally recognized EMC standards.

- EN 61326-1:2013

- EN 61000-3-2:2006, A1:2009, A2:2009

- EN 61000-3-3:2013

Conforms to EU Directive 2011/65/EU RoHS Compliance.

Packaging Films

- Monolayer

- Multi-layer

- Coated Films

- Coated Paper/paperboard

Specialty Films

- Gel/lotions

Packages

- Common food packages

- Medical packages

- Bottles/Closures

Test Standard Compliance

ASTM F2622

ISO CD 15105-2

JIS K-7126-B

DIN 53380-3

Test Methodology

Following ASTM F2622

Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and

Sheeting Using Various Sensors

The oxygen gas transmission rate is determined after the sample has equilibrated in a controlled test environment. Control of carrier gas flow rate (for concentration detectors), relative humidity, temperature, and oxygen concentration in both the carrier gas and permeant (test) gas chambers is critical.

The specimen is mounted as a sealed semi-barrier between two chambers at ambient atmospheric pressure. A stream of nitrogen slowly purges one chamber and the other chamber contains oxygen. As oxygen gas permeates through the film into the nitrogen carrier gas, it is transported to the detector where it produces a signal representing the oxygen transmission rate.