Introduction

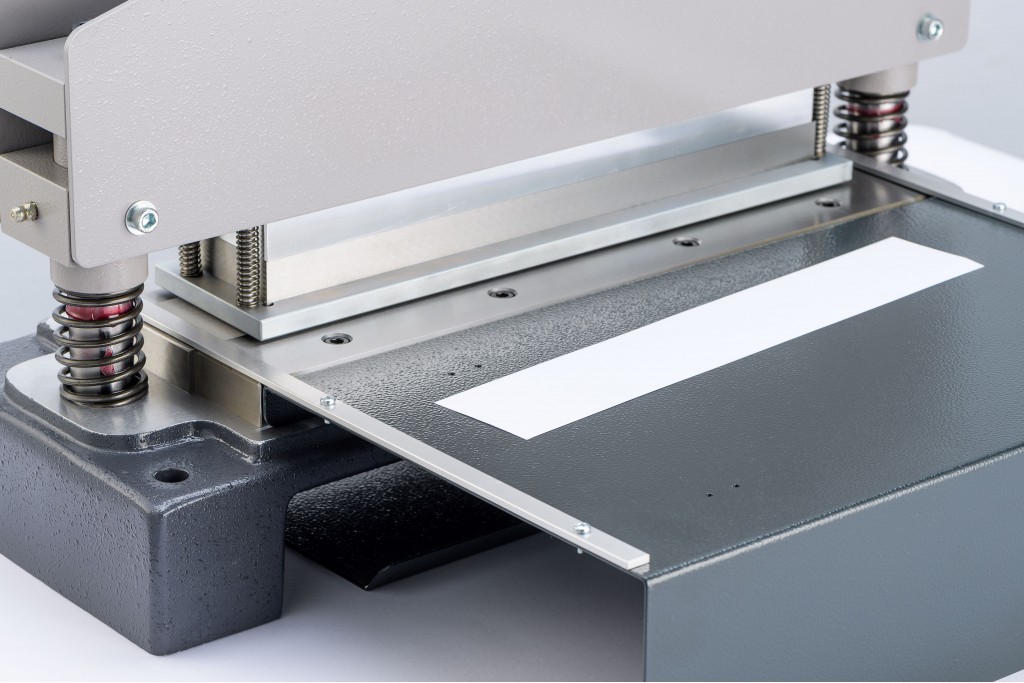

The accuracy of test results is not only dependent on the accuracy with which the procedure is carried out, but also on the accuracy of cutting the test pieces (specimens) from the original sample. Some tests, for example, tensile strength and edge crush, are particularly sensitive, and cutting accuracy is a prime cause of variation in the values obtained. These precision cutters are designed to eliminate the causes of errors associated with hand-cut samples.

Sample preparation is very important for the end result of the test. One mm difference on a 15mm width sample gives 6% deviation. This rectangular cutter with two solid gliders and a robust frame gives perfect accuracy and a long lifecycle.

Paper Tray – Since the samples fall in a special tray after bring cut, you can continue cutting several samples in a row without having to remove the samples first.

Sharp Sample – The blades used are hardened enduring their life-span. The cutting width is calibrated giving you a sample with exact dimensions.

Change Blades – The frame of the cutter is solid and robust. Even though the blades wear over time, it is possible to replace them.

Specifications

Model: 22-22 Series

Max sample thickness: 3 mm

Manual operation

Dimensions: 135 x 600 x 440 mm (5.5 x 24 x 17.5 in)

Weight: 29 kg (64 lbs)

Instrument can be bolted to the table

Available dimensions

22-22-00-0001 Rectangular punch 6″ x 1/2″

22-22-00-0002 Rectangular punch 300 x 50mm

22-22-00-0003 Rectangular punch 300 x 25mm

22-22-00-0004 Rectangular punch 300 x 15mm

22-22-00-0005 Rectangular punch 7″ x 1″