Introduction

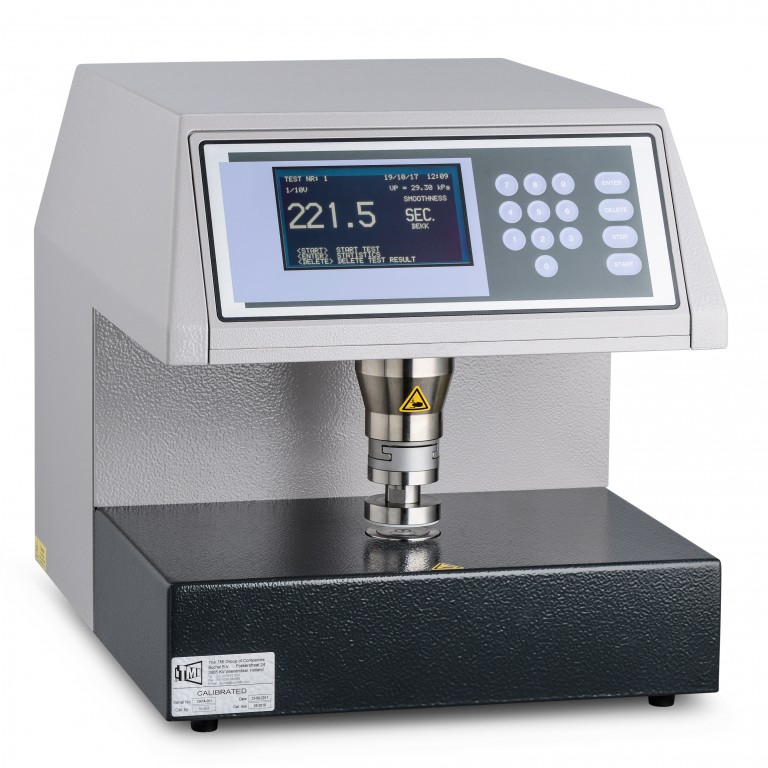

The Automatic Bekk Smoothness Tester is a microprocessor-controlled instrument for the determination of smoothness of paper and board according to the Bekk Method.

This air leak smoothness test is useful for very smooth surfaces, for example, coated label papers, coated free sheet, or other very smooth papers. Test results generate with the Bekk tester have shown excellent correlation with print smoothness evaluations using offset ink. Likewise, Bekk results have shown good agreement with subjective evaluations of low angle illuminated surface photomicrographs. Surface integrity is particularly important for printing papers. The surface fibers must be sufficiently bonded to those beneath the surface and the coating bond to the fiber matrix must be sound.

An innovative new feature is the Estimated Test Result. It was implemented to save the operator time when setting up a new test series and choosing the pressure interval and volume setting but also to save the operator time when doing a quick single test to see what the value of the paper approx. will be. The ETR value is calculated after the test has been started (50.66 kPa) based on the rate of rise of pressure. After 10 seconds the ETR value is displayed. During the test the ETR value is constantly re-calculated and updated until the ETR value at 48.00 kPa is the same as the final test result.

From Messmer Büchel BV, a TMI Group of Companies brand.

Features

- Open throat design enables large samples to be conveniently tested for rapid set-up and test

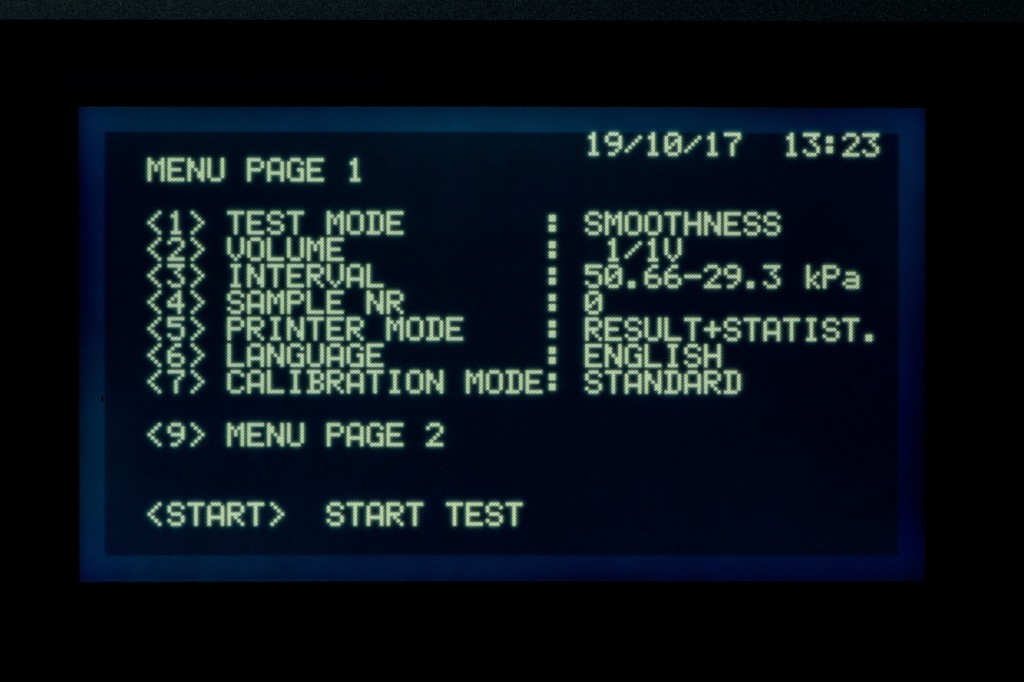

- Menu-driven software

- Air volumes 1/1 and 1/10th volume air receiver speeds up testing for smoother paper

- Pressure intervals 50.66-48.00 and 50.66-29.33 kPa

- Estimated Test Result: 10 seconds after start of test an ETR value is displayed, this represents the expected result at test completion

- Calibration adjustment using Paper tabs

- System check to check if the vacuum system is airtight

- Lists statistics on screen

- Multi-language standard

- RS-232 C serial data output

- Porosity Test Option

- Applications in Paper, Board

Specifications

- Estimated Test Result: Approx. 10 seconds

- Menu Selectable: Air volumes, Pressure interval

- Data collection: RS-232 C serial data output

- Display: Large black & white liquid crystal graphic high-contrast

- Calibrations: using Paper tabs

- Pressure Interval: 50.66-48.00 and 50.66-29.33 kPa

- Range: 0-99,000

Instrument Size

| Depth: | 530 mm (21 in.) | ||

| Height: | 415 mm (16.5 in.) | ||

| Width: | 390 mm (15.5 in.) | ||

| Weight | 51 kg (113 lb) |

Connections

| Electrical: | Specify voltage requirements when ordering | ||

| Air: | (instrument quality) 600 kPa |

Standards

DIN 53107, ISO 5627, TAPPI T 479

Properties

Roughness, Smoothness

Applications

Paper and Tissue Testing, Surface Property Testing

Industries

Corrugated and Board, Paper and Pulp