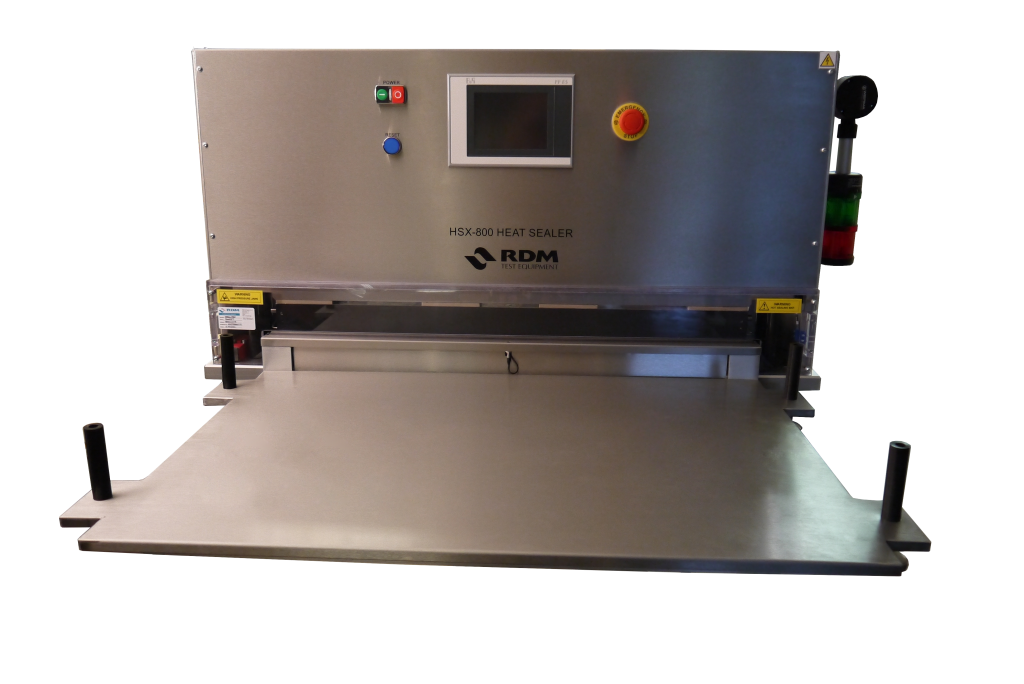

HSX-450/600/800 Medical Heat Sealer

Produces high quality heat seals in flexible medical packaging, max. 800mm. Validatable to ISO 11607. Touchscreen HMI/PLC controller, customisable.

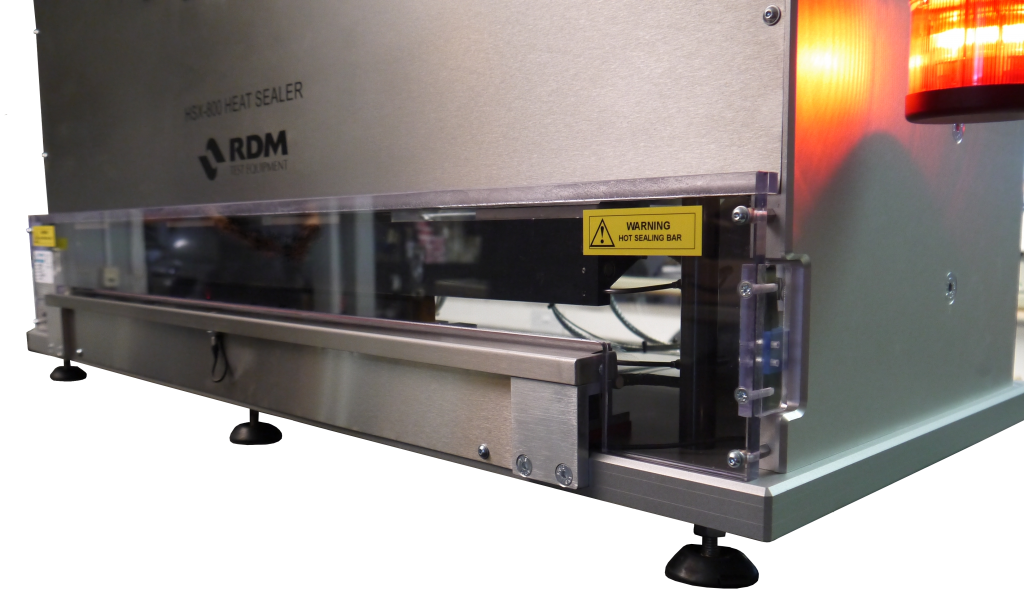

Producing flat, wrinkle free, high integrity seals can never be more critical than for sterile barrier flexible medical packaging; the HSX-Series provides the technology and reliability to produce time after time, independent of operator influence. Achieving seal integrity requires precision engineered constant heat sealing jaws and a pouch loading system that helps eliminate wrinkles, rather than creating them! The HSX-Series delivers controlled pressure, temperature and dwell time across the 400mm, 650mm or 800mm sealing jaws.

Validation of the process to ISO11607 Part 2 is simplified due to the HSX-Series touchscreen HMI and PLC controller. Process variables stored in recipes, are customisable behind multi-level passwords, and are constantly monitored triggering user alarms should any setting drift too far.

The HSX-800, and includes 800mm long sealing jaws, built-in touchscreen, ‘pack-in-place’ sensors, auto/manual start, and seal parameter trend analysis. Hardware add-on options include remote touchscreen controller, custom in-feed tray, additional ‘pack-in-place’ sensors, vacuum controlled packing, gas flush packing, and guillotine film cutter.

The HSX-Series is becoming the gold standard heat sealing equipment for highest quality seals in medical packaging.

Benefits:

- Choice of models and options with heat sealing jaw configuration, either single heated or dual heated

- Validatable to ISO11607, or internal standards, IQ/OQ documentation available

- High quality repeatable seals, not influenced by operator

- Versatile applications for flexible materials, such as polymer films, laminates, Tyvek, metallised films and foils

- Low Maintenance – 12 months between calibrations

Features:

- 5.7″ touch screen user interface/controller for precise control of temperature, pressure and dwell time. Integral screen as standard or separate control console optional.

- Storage of recipes for fast and repeatable recall of machine settings

- Precise pressure calibration of standard surface area jaw face

- Jaws constructed in aluminium and silicon rubber with precision ground faces

- Range of jaw face surfaces including Flat Metal, Crimp and Teflon Coating

- Auto start feature and cycle counter with reset, for greater user convenience

Leak & Burst

- Technology: Mass Flow & Piezoresistive sensors

- Accuracy: +/- 2% full scale

- Resolution: 0.1 ml/min & 0.1 mbar

- Scale: 1000 ml/min & 1.5 bar

- Sensitivity: 10 microns @ 20mbar & 5 microns @ 500mbar

- Mains cassette cord

Laboratory Requirements

| Temperature | ||

| Operation | -10 °C to 40 °C |

Accessories

Recommended

- 3052010526 In Use Cover for Indicator

- 2050013351 Indicator Stand

- 1100011297 Relay Box

Recording data

- 3074010266 RS-232 Cable 9F-9F

- 3074010507 RS-232 to USB Adaptor

- 1120015779 ATP2 Thermal Printer

600002028 AdamDU Data Collection Program

- Weighing

- Checkweighing

- Parts Counting