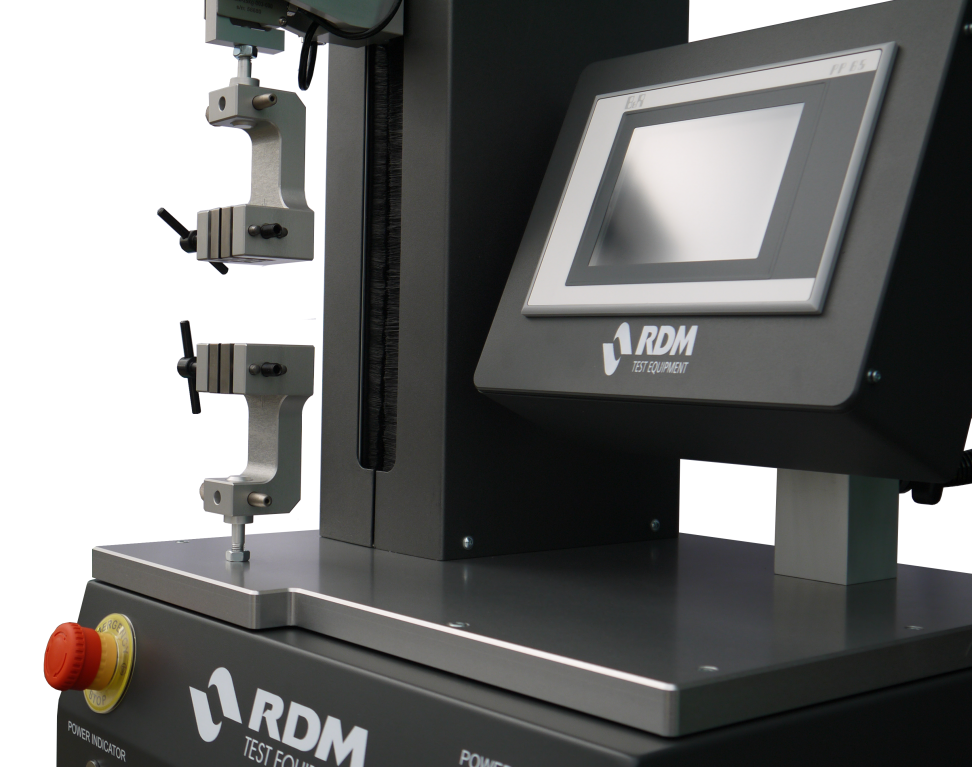

SST-3XS Seal Strength / Tensile / Compression Tester

Touchscreen Precision Seal Strength / Tensile / Compression Tester for determining the strength of packaging materials including plastics, paper and board.

Producing consistent and repeatable packaging for your product not only ensures minimal handling damage, but is vital in delivering a consistent brand to your customers. Precise measurement of the mechanical properties of materials and final packages is one way to ensure consistency and reduce material costs.

Accuracy and versatility in testing is vital, and the SST-3XS provides the technology and range of options to deliver for your specific needs. An intelligent controller and touch screen user interface stores multiple settings for later recall, and controls settings to ensure calibrated accuracy to international testing standards.

Benefits:

- Versatility to meet many international testing standards with packaging testing grips and attachments

- Integral controller and data analysis for stand alone use in laboratory and production environments, optional pc data acquisition

- Convenient built in graphical display of test data and trends over multiple samples

- Simple test set up and memory of settings for later recall makes switching between methods fast

- Low Maintenance – 12 months between calibrations

Features:

- 5.7″ touch screen controller for precise control and measurement of force, distance and speed

- Memory recipe function for quick and accurate recall of settings

- Standard 100N load cell, optional to 500N, interchangeable

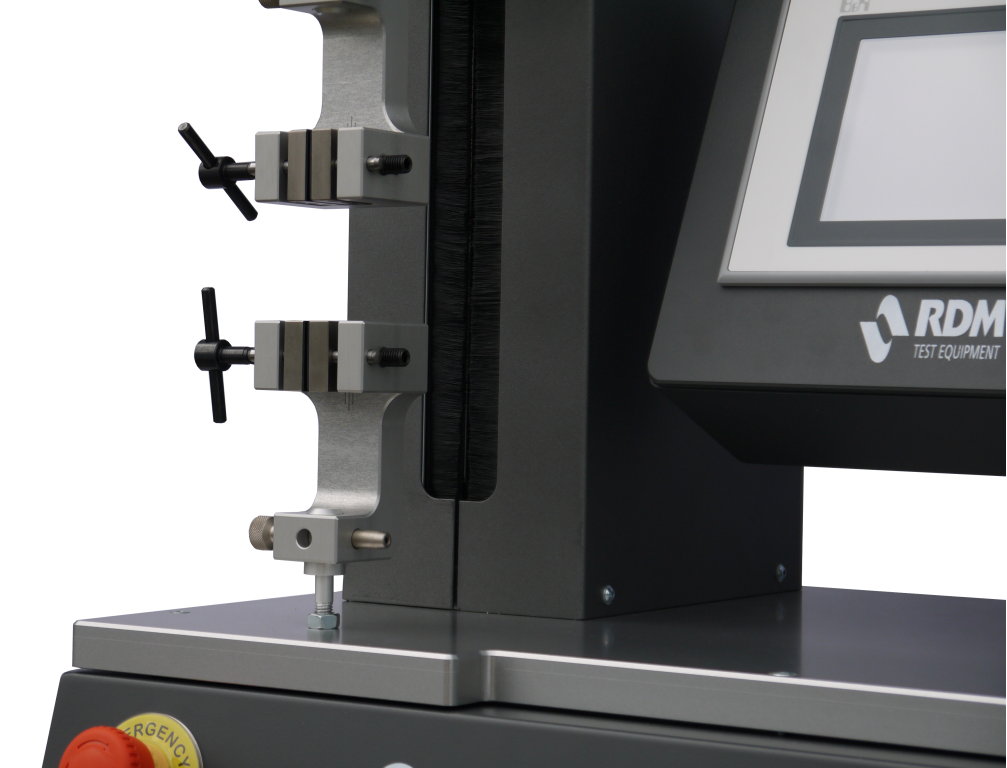

- Standard 300mm crosshead travel, optional 550mm travel

- Models: SST-3XS Mini (300mm travel) SST-3XS Maxi (500mm travel)

- Drive Mechanism: DC synchronous motor and gearbox with ball screw and crosshead

- Speed Control: 1mm/min to 1000mm/min +/- 0.5%

- Speed Feedback: Via in line encoder

- Touch Panel Screen: LCD, 256 Colour, QVGA, 320 x 240 pixels, 14.48cm diagonal viewing Touch screen, analogue resistive (gonze) with serial controller Processor Geode SC2200. 266 MHz MMX compatible. 2 mbyte, on board flash memory for firmware 64 MB Dram main memory

- Load Range: Selectable load cell;

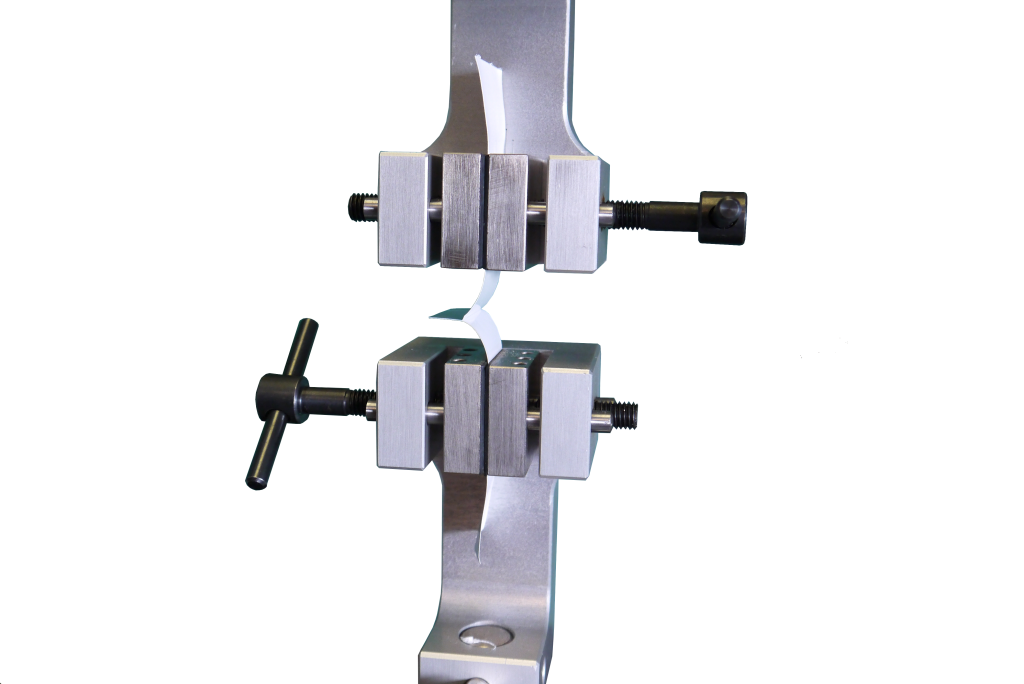

- Standard Grips: Light duty side entry vice grips

- Travel: 300 mm or 550mm effective travel

- Output: RS 232

- Power: 80 – 240 VAC single phase 50/60 Hz 500W Max

- Environment: 5-50°C ambient operating temperature, RH 75% max (non-condensing)

SST-3XS Seal Strength Tester meets the following standard, click on the link to purchase the standard ASTM F88.

RDM Test Equipment have set the standard in precision and reliability for over 30 years. Please Contact Us and we’ll work with you to understand your requirements and provide a solution.

Cartridges & Options

- Reduced area cartridge

- Edge effect cartridge

- Custom Engineered Test Cartridges

- Package testing adaptor

Consumables

- Cert Films 1-3 & set

- Special reference films at higher ranges

- Calibration gas kit for 2/12T

- Masks

Software

- PermWare data collection, data management and instrument status dashboard

- 21 CFR Part 11 user and data security

- Remote viewing software from a PC – PermNet Lite

Service & Support Options

- IQ/OQ documentation & validation

- Basic Preventative Maintenance Plan

- Plus Preventative Maintenance Plan

Packaging Films

- Monolayer

- Multi-layer

- Coated Films

- Coated Paper/paperboard

Specialty Films

- Gel/lotions

Packages

- Common food packages

- Medical packages

- Bottles/Closures

Test Standard Compliance

ASTM F2622

ISO CD 15105-2

JIS K-7126-B

DIN 53380-3

Test Methodology

Following ASTM F2622

Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and

Sheeting Using Various Sensors

The oxygen gas transmission rate is determined after the sample has equilibrated in a controlled test environment. Control of carrier gas flow rate (for concentration detectors), relative humidity, temperature, and oxygen concentration in both the carrier gas and permeant (test) gas chambers is critical.

The specimen is mounted as a sealed semi-barrier between two chambers at ambient atmospheric pressure. A stream of nitrogen slowly purges one chamber and the other chamber contains oxygen. As oxygen gas permeates through the film into the nitrogen carrier gas, it is transported to the detector where it produces a signal representing the oxygen transmission rate.