HT-2PC Automatic Hot Tack Tester

Hot Tack Tester with automatic film feeding device for determination of the hot tack seal strength of packaging films, to ASTM F1921.

The HT-2PC Hot Tack Tester is a highly technical instrument designed to measure the ‘Hot Tack Seal Strength’ of flexible packaging materials. It follows the principles of ASTM F1921 Standard Test Method for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and blends comprising the sealing surfaces of flexible webs.

What is Hot Tack Seal Strength?

Hot Tack Seal Strength is a measure of the strength of a hot heat seal tested within milliseconds after heat sealing. On production packs, newly formed hot seals are frequently exposed to disruptive forces, such as when contents are dropped into the pouch. These force act on the hot seal and if there is inadequate resistance they can break all or part of the seal. Therefore it is essential to measure the amount of stress the seal can withstand.

The HT-2PC has been designed to test the hot seal strength under accurately controlled conditions, simulating the stresses a pack is exposed to on a high speed packaging line. A heat seal that has cooled to ambient temperature will reach its maximum seal strength after several minutes or even hours. Measuring strength of cooled seals prepared on a Lab Heat Sealer and tested on a separate Tensile Tester does not correlate with the strength of a hot seal.

Principle of Operation

HT-2PC Automatic Hot Tack Tester replicates the heat sealing processes employed on automatic packaging lines in particular VFFS packaging machines, combined with a high speed tensile tester.

The operator chooses (or creates) a ‘parameter template’ from the library which sets the machine to test at defined values for temperature, pressure, dwell time, cooling time and peeling speed. The template can be a Single Test, Replicate Test, Sequential Test or Seal Initiation Test. These are then loaded to the ‘Playlist’. Film is loaded either manually for a single test, or a long strip is wound onto the film feeding device.

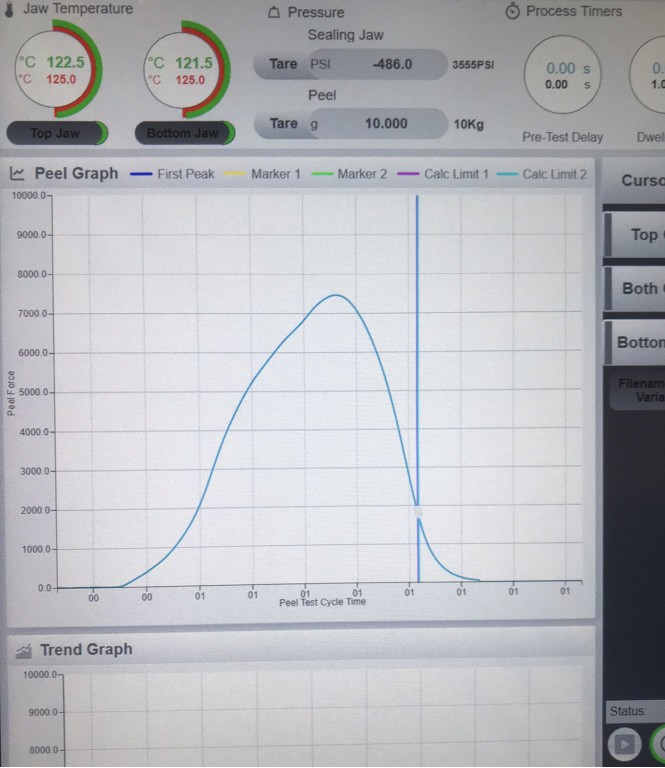

Once the playlist is started everything is sequenced automatically. The film is pushed into the sealing jaws, and is clamped. The hot sealing bars close to the desired pressure and after the dwell time elapses the jaws open. Next, the programmed cooling time runs down and then the sealed film is peel open at the test speed. All measurements of the seal properties are recorded at high speed to ensure transient forces are captured accurately. The results are displayed and saved automatically on the industrial pc, and saved for later recall, reporting or export to other software. The playlist then increments to the next test, the film is indexed to the next position and the test sequence starts again.

Parameter Templates

Parameter templates are used to load the required test settings. These are Single Test, Replicate Tests, Sequential Tests or Seal Initiation Tests. PLC control of all the parameters enables simulation of production packaging machines. A wide range of setting for each parameter enables testing of various materials to suit each application:

• Sealing temperature for top and lower sealing jaws, set individually.

• Sealing pressure

• Sequence timers for Delay Time, Dwell time, and Cooling Time

• Peeling speed

• Output configuration

Automatic Film Feeding Device

The Film Feeding Device is conveniently located in the front panel allowing easy use and access to the most frequently used parts. The clamps are easily loaded and clamp the film automatically once the test has been activated. Vertical movement of the lower clamp is controlled by an electric motor that enables accurate positioning and speed control through an encoder. The film folding devices sets the film up ready for sealing and the sealing is made through The sealing bars incorporate the heating element and sensors to complete the feed back loop of the PID temperature control.

Data Capture

The software is designed to be user friendly with drop down menus and easy key-strokes. The software is con-trolled through the touch screen (or keyboard and mouse) for parameter setting, measuring and data recording and storing for later recall. The software enables efficient use of the instrument by any person involved in testing, from production machine operators to quality control and R&D personnel. Report-ing is via a clear easy to read graphical media which shows each test and at the end of the test or series an overlay of test results.

Benefits:

- Automatic film feeding for fast, operator independent test results.

- Up to 40 hot tack tests per strip without need for operator supervision, with film sensor that pauses if the film breaks or runs out.

- ‘Parameter templates’ for Single Test, Replicate Test, Sequential Test and Seal Initiation Test, giving simple and fast set-up.

- A playlist (like a music playlist), that automatically advances tests.

- Fully automatic PLC control of all test parameters

- Industrial PC with USB and Ethernet connectivity

- Meets standard ASTM F1921

Features:

- Easily exchangeable jaws

- Low maintenance

- Easily calibrated

- Optional film feeder for fully automatic measurements

- Industrial PC with 15″ touch screen

- 10mm wide seal x 40mm long as standard (5mm and 15mm optional)

HT-2PC Software Features

User Interface:

Graphical user interface operated from one ‘Home’ screen

Touchscreen, with optional use of keyboard and mouse.

15” swing arm panel PC with Intel Atom CPU using a Windows-style interface for

ease of use and visibility of operations.

User access controls for Admin, Supervisor and Operators

Set Up:

Parameter templates for Single, Replicate, Sequential or Seal Initiation Tests.

Save user defined parameters, temperature, pressure, timers, peel speed.

Define variable parameter within a batch.

Add custom fields for traceability, e.g. batch number

Choose results to be viewed in results table

Measuring:

Batch of tests saves to a single file for a series of measurements

Variable parameter (temperature, pressure, time) per file.

Exclusion of measurements instead of deletion

Setup a playlist of measurements

Re-arrange, add or delete tests from playlist during measuring

Analysis:

Tabular view of measurement results

Add calculated results to the tabular view

Cascade of results for multiple measurements

View included and/or excluded samples

Sorting of results in tabular view

Copy measurements and graph to clipboard

User definable columns in tabular view

Import/Export/Reports:

Export to Microsoft Excel®

Merge data into Microsoft word® template

Custom Export using Javascript

Export to text

Print only selected items and save those layouts for later use

Print preview

Other Features

HTML help file

Engineer access to calibration values within the program

Specification

Sealing specification:

• Sealing bars: 2 x brass sealing jaws mounted with sensors and heaters

• Sealing bars: 10 x 40mm standard (5mm and 15mm optional)

• Sealing operation: symmetrical, two sided

• Sample width: max 30mm

• Sample thickness max 1mm

• Sealing dwell time: 0.01 to 99.99s

• Sealing temperature: ambient to 350˚C

• Sealing pressure: 0.1 to 3.0 N/mm2

• Sealing pressure control: electronic PID

• Sealing pressure sensor: Strain gauge

• Sealing temperature control: electronic PID

Peeling specification:

• Cooling time: 0.1 to 99.1sec

• Peeling speed: 1 to 750mm/s

• Peeling by vertically moving lower sample clamp

• Peel control: electric servo motor

• Sample length: min 300mm

Hot tack force measurement:

• Measurement range: 0 to 100N

• Sampling speed: max 20kHz depending on peel speed

• Number of readings: 2000 per measurement

• Sensor: Piezo electric force transducer

Testing Mechanics:

• Sample clamps: 2 auto air activated

• Sample folding tongue: auto servo motor controlled

• Optional full automatic measuring mode

Software:

• Compatibility: Microsoft Windows® 7/10

• Touch screen operated interface

• Setting, storing and re-calling of test parameters

• Storing, re-calling and reporting of measuring results

Reporting:

• Measurement results: hot tack force vs cooling time graph

• Measurement results: hot tack force vs temperature graph

• Analysis: graphs from testing sequence vs variables

• Numeric: reporting with data export capabilities

Outputs:

• USB and Ethernet connections

Connections:

• Power: 85 to 250VAC, 50/60Hz 180VA

• Air supply: 6 to 8 bar clean dry compressed air

Physical:

• Weight: 60kg

• Size: 430W x 430D x 700H mm

Design:

• Made to work to international sta

HT-2PC Hot Tack Tester meets the following standard, click on the link to purchase the standard ASTM F1921.

RDM Test Equipment have set the standard in precision and reliability for over 30 years. Please Contact Us and we’ll work with you to understand your requirements and provide a solution.

Removable Cartridges

- Easy sample prep on the benchtop

- One button release and loading

- Pneumatic clamping provides more repeatable results

- Interchangeable cartridge options extend the range and flexibility of the analyzer without tools while maintaining arcuate results

- Cartridge options include: Reduced area to extend testing range without masks, improved accuracy testing of coated paper-based barriers, adaptors for remote testing of packages or extreme conditions, and custom designs for unique testing requirements.

TruSeal®

- Gas flush of sample mounting seal protects chamber integrity

- Lowers background level reducing need to run individual zero

- Shortened testing time increases throughput

- More repeatable results

Control Features

- Fully automated flow, temp, & RH control throughout tests

- Automatic test method development and recommendations

- Programmable multi-test sequencing

- Final test report printing and export

- Built-in sensor protection

Touchscreen Interface

- Intuitive automated operation requires less training

- Built in multi-level user management and data security

- Event log & trouble shooting guide

- Save on valuable lab space by eliminating need for PC

Accurate Sensors

- 2/12 R model has wide range sensor providing reliable, repeatable results

- 2/12 T model has a unique high range Coulox sensor for high transmitter barriers

Warranty

- Full 100% parts and workmanship warranty for 12 months

Capabilities – Model-Specific

| Units | R Model | T Model | |

| Test Ranges (50 cm^2 @100%O2) | cc/(m2 × day) | 0.05 to 28,800 | 200 to 65,000 |

| cc/(100 in2 × day) | 0.003 to 1858 | 12.9 to 4200 | |

| Test Ranges (5.6 cm^2) @100%O2 | cc/(m2 × day) | 0.44 to 255,300 | 1770 to 576,200 |

| cc/(100 in2 × day) | 0.027 to 16,470 | 114 to 37,200 | |

| Test Range – Package | cc/(pkg × day) | 0.00025 to 144 | 1.0 to 323 |

| Resolution | cc/(m2 × day) | 0.05 | 2.0 |

| Repeatability | cc/(m2 × day) | 0.05 or 1.5%* | 25 or 1%* |

| Test Temperature Range | °C | 10° to 40°C ± 0.2°C | 10° to 35°C ± 0.2°C |

| Controlled RH Testing Range | % RH | 0 to 90% ± 3% | 0% |

*whichever is greater

Capabilities – All Models

| OX-TRAN 2/12 Series | Units |

| Film Size | 4” x 4” Std, 2”x2” optional |

| Film Thickness | Up to 120 Mil |

| Film Test Area | 50 cm2 cartridge std, |

| 5.6 cm2 cartridge optional |

Other Specifications (all models):

Physical Specifications

- 5.5” H x 12” W x 23” D (39.4 cm x 30.4 cm x 58.0 cm)

- 95 Lbs. (43.1 kg)

Electrical Requirements

- Voltage: 100 – 240 VAC 50/60 Hz

- Maximum Power Draw: 700 VA

Laboratory Requirements

| Temperature | Operation | 22 °C ± 2 °C |

| Storage | 10 °C to 30 °C | |

| Humidity | Operation | 20% to 80% RH (non-condensing) |

| Storage | 5% to 85% RH (non-condensing) |

Gas Supply Requirements

| Carrier Gas | Gas Composition | 100% Nitrogen |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) | |

| Test Gas | Gas Composition | 100% Oxygen (purity 99.9%) |

| Supply Pressure, Nominal | 29 PSI, (2.0 Bar), (200 kPa) |

Connectivity

- Remote Access and Control (requires optional Perm-Net Light software)

- Standard Ethernet port (100T)

- Dual USB 2.0 ports (for connection of keyboard, mouse or memory devices)

Compliance Standards

This product is UL and CSA listed using the ETL mark from Intertek Group plc. and is certified to conform to CE.

Conforms to the following internationally recognized safety standards.

- IEC 61010-1:2010 Third Edition

- UL 61010-1:2012 Third Edition

- CAN/CSA-C22.2 No. 61010-1:2012 Third Edition

Conforms to the following internationally recognized EMC standards.

- EN 61326-1:2013

- EN 61000-3-2:2006, A1:2009, A2:2009

- EN 61000-3-3:2013

Conforms to EU Directive 2011/65/EU RoHS Compliance.

Packaging Films

- Monolayer

- Multi-layer

- Coated Films

- Coated Paper/paperboard

Specialty Films

- Gel/lotions

Packages

- Common food packages

- Medical packages

- Bottles/Closures

Test Standard Compliance

ASTM F2622

ISO CD 15105-2

JIS K-7126-B

DIN 53380-3

Test Methodology

Following ASTM F2622

Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and

Sheeting Using Various Sensors

The oxygen gas transmission rate is determined after the sample has equilibrated in a controlled test environment. Control of carrier gas flow rate (for concentration detectors), relative humidity, temperature, and oxygen concentration in both the carrier gas and permeant (test) gas chambers is critical.

The specimen is mounted as a sealed semi-barrier between two chambers at ambient atmospheric pressure. A stream of nitrogen slowly purges one chamber and the other chamber contains oxygen. As oxygen gas permeates through the film into the nitrogen carrier gas, it is transported to the detector where it produces a signal representing the oxygen transmission rate.