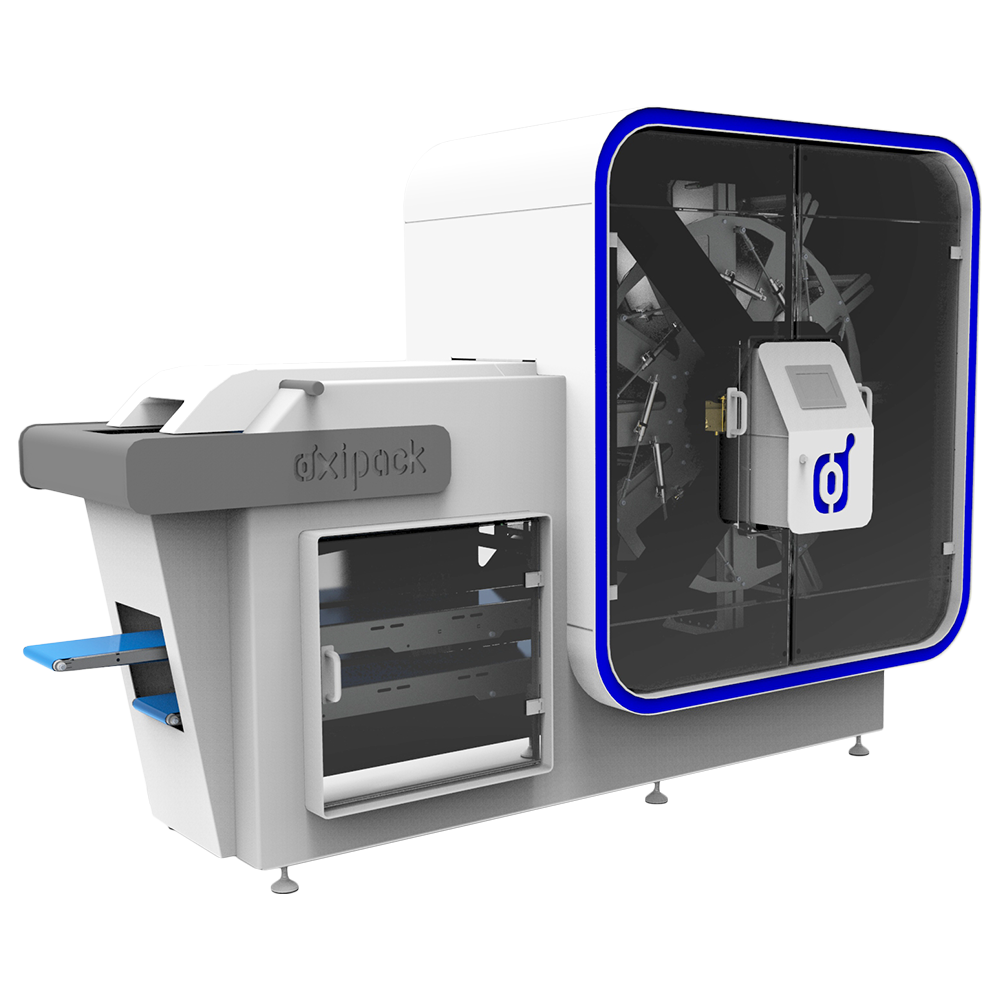

The Rotator R-20 up to R-120

The Oxipack Rotator is an automated, in-line leak detection solution for flexible MAP-packages, enabling you to maintain complete control over the process and the quality of your production line. The tester has a testing capability from 20 up to 120 packages per minute.

The Rotator is fully integrated into the production line, ensuring a seamless and streamlined integrity check. The universal chambers of the Rotator allow for simultaneous testing of different MAP packaging types, providing instant feedback on the package integrity of your products. Maintenance is made easy with

removable chambers.

Working principle: packages are presented to the Rotator’s conveyor belt, where they are positioned on a shooting belt that places them into the test chamber. The chamber consists of a rigid bottom plate and a flexible membrane top, which

closes when the package is inserted. The machine then rotates to the next position, and the leak test begins by creating a vacuum. The next package is inserted into the chamber, and the cycle repeats. Once all packages are tested, the chamber opens, and the packages are sorted onto either the reject or OK belt. The rejected packages are directed to a separate bin for inspection, while the OK packages continue down the production conveyor belt.

- Large, customisable 12.7cm 800×480 pixel touchscreen display

- Icon-driven menu so anyone can use the balance

- Select from preset applications such and formulation and checkweighing, complete with on-screen guidance

- USB/RS-232 port for transferring GLP-compliant data to USB stick

- Optional printer for printing weight, date, time and more

- Large, grade 304 stainless steel pan allows easy cleaning

- Built-in memory for storing products and settings

- Selectable digital filtering helps minimise effects of vibration and disturbances

- Security password control prevents unauthorised access

- Multilingual display allows use in many different countries

- Checkweighing with audible alarm

- Memory accumulation totals results

- Parts counting with freely selectable sample sizes

- g, mg, ct, GN, lb, oz, dwt, mm, ozt, tI.H, tI.S, tI.T, T weighing units

Warranty

- 5 year manufacturer’s warranty

Model Capacity Readability Beam Size (each)

| AELP 1000 [GK] | 1000kg | 0.2kg | 120 x 1330mm |

| AELP 2000 [GK] | 2000kg | 0.5kg | 120 x 1330mm |

| AELP 3000 [GK] | 3000kg | 1kg | 120 x 1330mm |

- Mains cassette cord

Laboratory Requirements

| Temperature | ||

| Operation | -10 °C to 40 °C |

Accessories

Recommended

- 3052010526 In Use Cover for Indicator

- 2050013351 Indicator Stand

- 1100011297 Relay Box

Recording data

- 3074010266 RS-232 Cable 9F-9F

- 3074010507 RS-232 to USB Adaptor

- 1120015779 ATP2 Thermal Printer

600002028 AdamDU Data Collection Program

- Weighing

- Checkweighing

- Parts Counting